MS1-Extra Ignition Hardware manual

Only for use with the MS1 Extra code (MS1 - 68H908 based microprocessors)

By Philip Ringwood (daxtojeiro), James Murray (jsmcortina) and Ken Culver (muythaibxr)

|

MS1-Extra Ignition Hardware manual Only for use with the MS1 Extra code (MS1 - 68H908 based microprocessors) By Philip Ringwood (daxtojeiro), James Murray (jsmcortina) and Ken Culver (muythaibxr) |

|

Before you start any hardware mods please read this entire manual and the Software Manual, available HERE. |

Warning

for

E-Bay buyers!! Please see the Official Suppliers list before buying through E-Bay. This is there for your protection. |

|

Please Note:

All of these instructions / diagrams are to be used at your own risk, like most things there is more than one way to do the same thing, what we have tried to do is to offer a method that we have tested or that others have tested for us. No warranty expressed or implied. Use at your own risk. |

Select the Ignition Setup Option for your vehicle. Next select the Trigger Input Option (depending on what Version of MS PCB you have) for the trigger type that's fitted to your engine. Then select the Spark Output Option for your setup.

Layout of MS PCB's for V2.2 -- for V3.0 -- for V3.57

Component Schematics -- List of Component Part Numbers

Distributor Based Single coil Setup (MSnS) -- Neon/420A Decoder -- Wheel Decoder

Ford EDIS Ignition System -- Ford TFI Ignition --GM 7pin HEI ignition -- GM DIS Ignition -- Buick Computer Controlled Coil Ignition (C3I)

5 Cylinder Engines (Audi, etc) -- 4G63 powered DSM (Eclipse / Talon / Laser) -- SOHC Mitsubishi and Proton -- Rotary Engines -- Toyota VAST

Trigger Input Options for V2.2 PCBs (green pcb):

Hall or Optical input sensor wiring for V2.2 PCB -- VR input Sensor wiring for a V2.2 PCB -- Eliminating Cross Talk and Wiring Considerations for VR Sensors

Second VR Sensor Input for a V2.2 PCB -- Second Trigger Input

Luminition Optical Input for a V2.2 PCB -- Distributor points input for a V2.2 PCB

Trigger Input Options for V3.0 PCBs (blue pcb):

Hall or optical input sensor wiring for a V3.0 PCB -- VR input Sensor wiring for a V3.0 PCB -- Eliminating Cross Talk and Wiring Considerations for VR Sensors

Second VR Sensor Input for a V3.0 PCB -- Second Trigger Input

Luminition Optical Input for a V3.0 PCB -- Distributor points input for a V3.0 PCB

Spark Output Options for V2.2 PCB (green pcb):

MSD Amplifier (6A) output diagram for a V2.2 PCB -- Bosch Ignition Modules

Single Spark Coil Direct Drive Output from MS ECU for a V2.2 PCB

Two or more Spark Coils Direct Drive Output for a V2.2 PCB

Driving two coils from the same spark output e.g. wasted spark coil on plug (COP)

Spark Output Options for V3.0 PCB (blue pcb):

MSD Amplifier (6A) output diagram for a V3.0 PCB -- Bosch Ignition Modules

Single Spark Coil Direct Drive Output from MS ECU for a V3.0 PCB

Two Spark Coils Direct Drive Output for a V3.0 PCB -- Multiple Spark Coils Direct Drive Output for a V3.0 PCB

Driving two coils from the same spark output e.g. wasted spark coil on plug (COP)

Layout of the Megasquirt PCB's

V2.2 PCB:

Topside view of V2.2 pcb (these are green pcb's)

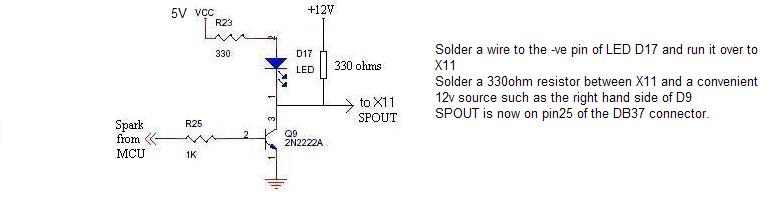

The V2.2 PCB has 4 spare connectors (X11 to X14) these can be used for various inputs and outputs for the following circuits as they are conveniently available on the 37pin DB connector:

X11 = pin 25 of 37pin db

X12 = pin 27 of 37pin db

X13 = pin 29 of 37pin db

X14 = pin 31 of 37pin db

The V3.0 PCB has 4 spare connectors (SPR1 to 4) these can be used for various inputs and outputs for the following circuits as they are conveniently available on the 37pin DB connector:

SPR1 = Pin3 of 37pin db

SPR2 = Pin4 of 37pin db

SPR3 = Pin5 of 37pin db

SPR4 = Pin6 of 37pin db

As can be seen, theres no proto area on the V3.57 and the components are very small. So soldering wires onto the board for spark outputs, hardware options, etc, is going to need a great deal of care. You may even have to remove some parts, which is not easily done to surface mount components, so I don't feel these manuals should cover doing this, as damage is very easy to do. Also a daughter board will need to be built if you want some of the hardware options as theres no proto area to build on. I have therefore assumed if you bought a V3.57 that you will not be modifying it to use the hardware functions such as Tacho out, PWM Idle valves, Boost control, Launch input, etc, etc. If you do wish to use these then you will have to build a daughter board of some form to mount the components on. If you use more than 2 spark outputs youll need to use the db15 connector, but ensure you strengthen the traces on the board with copper wire or solder to the pin directly, also connect the outputs in pairs of pins, as per the instructions HERE.

Note that the JS0 - JS11 pads are all electrically the same as the V3.0 PCB as are the SPR1 - 4 pads, so they can be used in the same way as the V3.0 PCB. The addition is JS12 which is the same as the bottom of R1 on the V3.0 pcb, but R1 will still need to be removed to use it on the V3.57, so be very very carefull !!!

Suggested points for Supplies inside the V3.0 ECU

List of component part numbers used in the ignition section:

|

DigiKey

part numbers:

|

Farnell

part numbers

|

|

2N2222A = 497-2598-5-ND |

2N2222A = 920-7120 |

Please note: Above part numbers will need checking, some components will come with a minimum order in multiples of 5 and 10.

More specific details on MSnS setups (Distributor based)

Ensure only LED17 (D14) is set as a spark output (Spark OutputA) there must be NO other Spark Outputs selected!!!

This mode is for use with a single coil distributor allowing

you to control your timing if you have a single coil firing

through a distributor, an MSD 6A amplifier, etc.

Your tach signal into the Megasquirt can come from a crank trigger or from

a "locked" distributor (dizzy) using hall, points, inductive VR

or opto sensors.

This mode requires ONE Trigger per Spark Event,

e.g. 2 pulses from a crank on a 4cy or 4 pulses from the disrtibutor

on a 4cy (distributor runs at half the speed of the crank) , 4 pulses

from the crank on a V8 or 8 from the distributor on a V8, etc.

If your engine has a toothed wheel (e.g. a 60-2, 24/2, 36-1, etc) then you

must NOT use MSnS mode, setup the WHEEL

DECODER MODE instead, and select SparkA as the only spark

output whilst using the distributor.

A locked distributor is one that has mechanical and vacuum advance either

removed or "locked" out so that the trigger signal occurs at the

same crankshaft angle at all rpms. Many distributor cars with EFI already

have a locked distributor.

Crank triggering provides a more stable advance as there is no timing chain

or belt and distributor gear jitter. For a four cylinder engine you would

require two pips/lobes or bolt heads (giving 2 signal pulses) at 180 degrees

to each other and a VR / hall sensor, for a 6cy you will need 3 pulses per

crank revolution at 120deg intervals and 4 for a V8 at 90deg intervals.

(note that a crank rotates at half the speed of the cam drive). The V3 circuit

board can directly read from a VR sensor. The V3 board also provides a VB921

high current driver that will drive your single coil directly, this means

you dont need an amplifier/dwell controller. If you use a crank trigger

you do not need to modify your distributor. Just make sure that the internal

rotor points towards one of the towers when the engine is roughly in the

firing angle - if it is halfway you can easily get cross-firing between

cylinders.

Below is a general layout drawing of the V3.0 MS ECU and trigger sensor with the coil.

IMPORTANT - do NOT set your total Trigger Angle (i.e. Trigger

Angle plus additions) inbetween the range 20 to 50 degrees as you will encounter

problems and be unable to get your desired advance. If this is the Trigger

Angle you calculate then you either need to move your crank sensor/wheel

or modify your distributor to obtain a compatible trigger angle. This is

due to the way the ECU calculates the spark timing, the calculations need

around a 5deg band from the Trigger Angle.

e.g. If you set a Trigger Angle of 23 degrees (no additions) then your maximum

advance would be about 18degrees which will almost certainly give you a

very lame engine down on power.

If the Trigger Angle setting is less than 15 deg the code will use "Next

Cylinder" sparking, which means it will work out the timing for the

next spark rather than the current spark, this is perfectly acceptable.

Please note: VR sensor users must use "Time Based cranking" when in MSnS mode, this is in the Spark Settings page.

Hall sensor users can take advantage of "Trigger Return" In this mode the trigger should be active (5V - 12V) at least 5-10 degrees before maximum advance and stay active until 5-0 degrees BTDC. The trigger going low (0V) sets off the spark when cranking. This will give accurate advance during the uneven cranking period. The middle LED (LED18 - D15) on the front panel (When set to "IRQ TRIGGER" in the Codebase and Output functions) shows the current status of the trigger to make it easier to adjust the distributor, or whatever triggers the MS. LED on = trigger high, LED off = trigger low. This LED is only of real use for hall sensors and needs to be configured in TunerStudio. On "Codebase and Outputs function" set LED18 (D15) to IRQ trigger.

Hall sensor in Distributor setup

How you should connect a Hall sensor to the Megasquirt all depends on what

comes out of the Hall sensor.

1)Turn the engine until cylinder 1 is at approx 25 Deg BTDC.

2)Turn the distributor until the rotor points in the middle

of the contact for cylinder 1 in the distributor cap.

Sometimes you may need to "re-phase" your distributor to change

the angular relationship between the rotor arm and the vanes if using a

trigger inside it.

3)Make sure one of the metal finger edges are close to the

Hall sensor if using the distributor sensor to fire the MS, if your using

a crank sensor then ensure this is near an edge of one of the lugs of the

crank wheel.

Confirm the crankshaft angle - either using timing tape or

by estimating. For correct code operation you need a vane edge either in

the distributor or on the crank if using a crank sensor, to pass the trigger

when the engine is at 60-90BTDC OR 5-15BTDC. If it passes at 16-50BTDC you

MUST re-phase you distributor or move the crank sensor round or you

will be unable to set your advance correctly.

If modification is required, typically set the vane edge to pass the sensor

when the engine is at 60BTDC and have the rotor arm pointing directly to

the tower when the engine is at 25BTDC.

Turn the engine backwards until the edge is well out of the Hall sensor. Measure the output voltage from the Hall sensor Turn the engine forward until the edge has passed through the Hall sensor. Measure the output voltage.

If both voltages are low, attach a 1K pullup resistor (see HERE for a pullup diagram) to the output wire of the hall sensor. Test again.

For a V3 PCB connect the input as the Hall Sensor Input diagram (see HERE)

For a V2.2 PCB : If the output goes from high to low

you should use the Hi to Lo schematic HERE

If the output goes from low to high you should use the Lo to Hi schematic

HERE

A distributor is needed with the MSnS mode to distribute the spark the correct cylinder, since it only has one ignition output. If the distributor is used to trigger the ignition all advance mechanisms have to be locked.

The distributor may have to be modified to ensure that the

spark is delivered to the correct cylinder. The only important thing is

that the rotor arm points to the correct contact in the distributor cap.

The best bet is to get the rotor arm line up to a contact at about 25 degrees

before TDC. It is not important to get exactly this angle, some 10 degrees

before or after will be probably be OK, as long there is no risk for cross

fire (spark on wrong cylinder)

Setup - Hall sensor

First, in TunerStudio in the Codebase and outputs function, set LED18

to "irq trigger" and send to ECU.

1) Set the crank at TDC

2) Rotate the distributor (opposite direction) just until middle LED turns

OFF (sets the crank angle)

3) Make sure the rotor arm points towards the correct contact in the distributor

cap

4) Fix the distributor

5) Turn engine backwards until middle LED turns ON (should be almost immediately)

and continue turning until it turns OFF again

6) Measure angle BTDC (+/- 10 degrees is good enough) at the crank

7) Enter measured angle in "Trigger angle"

8) Enter "Fixed angle" to 10 degrees

9) Start the engine

10) Adjust "Trigger angle" until the timing light is at 10 degrees

11) Set "Fixed angle" to -10

12) Start tuning

Setup - VR sensor

1) Set the crank at 20BTDC

3) Make sure the rotor arm points towards the correct contact in the distributor

cap

4) Bolt down the distributor

5) Turn engine backwards until the pip lines up with the VR sensor

6) Measure angle BTDC (+/- 10 degrees is good enough) at the crank

7) Enter measured angle in "Trigger angle" of Spark

Settings

8) Enter "Fixed angle" to 10 degrees this tells the ECU

to ignore the spark map and hold it to the Fixed Angle.

9) Start the engine

10) Adjust "Trigger angle" until the timing light is at

10 degrees

11) Set "Fixed angle" to -10 , this tells the ECU to run

from the spark map again.

12) Start tuning

Here is a list of links to a superb section on Distributor based setups, showing more detail that the above.

|

|

MS Connections |

TunerStudio Settings* |

|

||

|

||

|

||

|

||

Malory Unilite (optical trigger) |

||

|

||

|

||

|

*All of the above TunerStudio settings are for Next Cylinder Mode. See below for an explanation of Next/This cylinder mode

Wiring for the Neon / 420A Decoder -- Setting the Software for Neon/420A

Chrysler/Dodge/Plymouth

The "Neon/420A" mode theoretically supports the following vehicles

when equipped with a 2.0 or 2.4 4cylinder Chrysler engine.

"NS" body models:

1996-2000 Chrysler Town and Country

1996-2000 Dodge Caravan/Grand Caravan

1996-2000 Plymouth Voyager/Grand Voyager

"JA" body models:

1995-02 Chrysler Cirrus

1995-02 Dodge Stratus

1996-2000 Plymouth Breeze

"JX" body models:

1996-02 Chrysler Sebring Convertible

"PL" body models:

1995-02 Dodge Neon

1995-2001 Plymouth Neon

"PT" body models:

01-02 Chrysler PT Cruiser

"FJ" body models:

1995-02 Chrysler Sebring Coupe

1995-2000 Dodge Avenger

Wiring for the Neon / 420A Decoder

Circuit Diagram for V3.0 PCB:

Wire the Megasquirts ECU's input section up as per this diagram in the input wiring section:

Wire the Output Section like this:

Remove, if fitted, link between IGN and IGBTOUT

Circuit Diagram for V2.2 PCB:

Wire the Megasquirts ECU's input section up as per this diagram in the input wiring section:

Wire the Output Section like this:

Diagram for V2.2 and V3.0 wiring:

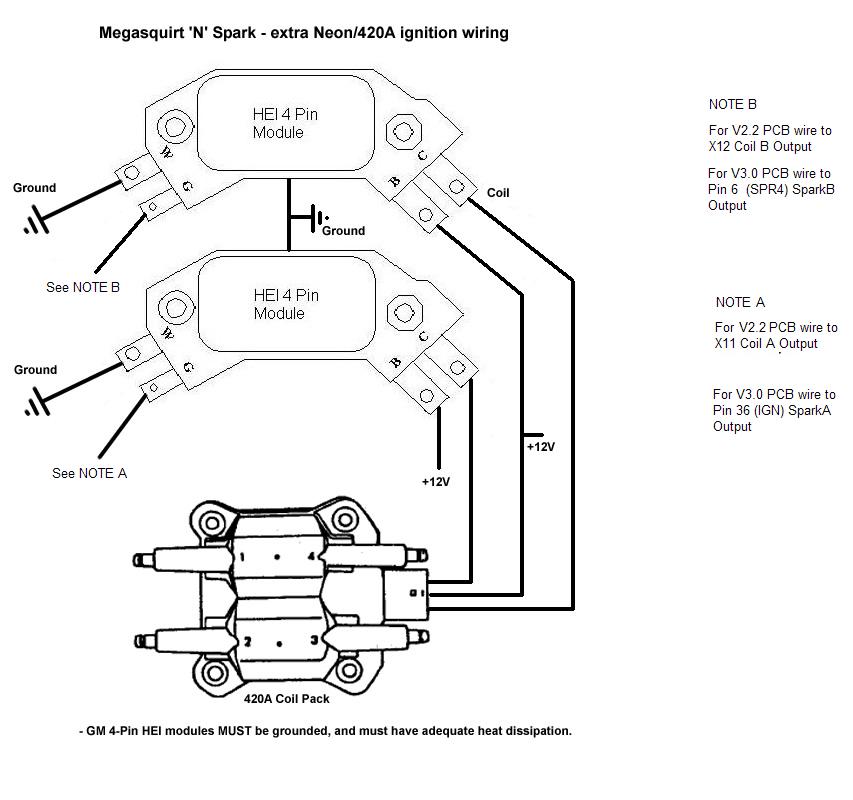

Next wire 2 x HEI 4 Pin Modules like this:

The wiring diagram attached shows the general wiring for a V2.2 or a V3.0 PCB Megasquirt, when installed on a 420A equipped Mitsubishi Eclipse / Eagle Talon.

Setting the Software for Neon/420A

In Ignition Options / Wheel Decoder and Output Pin Options ensire that NEON/420A is the only ignition option selected and that LED17 and LED19 are the ONLY 2 Spark outputs!!

Coil On Plug (COP) -- Where to mount the sensor and wheel -- Megasquirt hardware mods for 2 rotor with the NipponDenso -- Software Settings

The wheel decoder allows the use of a multi-toothed trigger

wheel such as 36-1 (commonly fitted to Fords), 60-2 (used mainly by Bosch

and therefore very widespread in Europe.) See www.trigger-wheels.com

for a supplier of custom made wheels. Other custom wheels such as 6-1 or

4-1 also work. Also supported are dual wheels such as the 24/2 wheels seen

on Mazdas and Toyotas. These have two wheels, one with 24 evenly spaced

teeth and a second pair of teeth with a second sensor. (See the Second Sensor

Input Section HERE)

The code supports:

Fuel only

Single coil (distributor based setup)

Wasted spark with multiple coils

It can also support coil per plug in some installs.

For wasted spark you require a minimum

of single "missing tooth" crank wheel, only engines with an even

number of cylinders being supported. You need at least 4-1 for 4cyl, 6-1

for 6cyl or 8-1 for 8cyl. However, the 36-1 wheel is probably the easiest

to obtain. The MS ECU can drive up to 6 seperate spark outputs, meaning

it can run up to a 12 cylinder in wasted spark mode. (4cy, 6cy, 8cy 10cy

and a 12cy)

Coil per plug can be achieved with a crank wheel and single-tooth cam wheel

OR a dual wheel cam setup OR a missing-tooth cam-wheel alone.

For a distributor based setup with a trigger wheel, simply follow all of the wheel decoder instructions but rather than setting SparkB, C, etc as outputs (as in a wasted spark setup) only set LED17 as SparkA output and ensure all other spark outs are NOT set:

LED17 (D14) = SparkA

LED18, LED19, Output3/SparkD, pin10 shift and knockin must NOT be a Spark output

The easiest install will be wasted spark using VB921 FET's to drive the spark coil(s) directly from a V3.0 PCB. (See the Spark Output selections available HERE) In this way it can be used like EDIS but without the need for an EDIS module, it has the advantage of allowing spark cut rev limiting. The downside is that it is more difficult than EDIS and requires extra software settings. If you are buying a pre-assembled Megasquirt your vendor will be able to do this for you.

The wheel decoder is a very powerful front end on top of the MSnS spark code that allows generic crank/cam angle wheels and vr sensors to be used with the Megasquirt for tach triggering, and ignition. Before setting up the wheel decoder, several questions should be asked:

1) How many cylinders (or rotors?) this will tell you how

often you get a firing event, and help with setup later.

8 cyl: 90 deg between firing

6 cyl/3 rotor: 120 deg between firing

4 cyl/2 rotor: 180 deg between firing

2) Where is your wheel going to be mounted, camshaft or crankshaft? This matters because the camshaft turns half a revolution for every crank revolution. This will also help determine how to set things up later.

3) Are you going to use a wheel with a missing tooth or a Cam Angle Sensor which actually has 2 wheels and 2 VR sensors.

4) Finally, how many teeth does your wheel(s) have?

5) When does the missing tooth (teeth) pass the sensor with respects to TDC or what tooth does the sensor see when the engine is at TDC?

When you have all this information, you're at least ready to start.

Where to mount the sensor and wheel

Lets asume your going to change a distributor based setup over to a wasted spark coil pack setup. The changes needed will be different for each engine but the basics should be the same: A wheel will need to be fitted on the crank pulley, a VR sensor will need to be mounted to detect the wheel and a set of coil packs will need to be mounted onto the car.

Typical trigger discs (36-1) from a Ford

Typical trigger discs (36-1) from a Ford  VR Sensor

VR Sensor

Mounting the wheel is quite critical in that it MUST be mounted so it rotates without moving up, down, left or right as the sensor needs to see all of the teeth with a gap of 0.75 - 1.0mm. The VR sensor can be found on virtually all Fords that have a coil pack under the bonnet, you'll need the coil pack too, so get them both at the same time, also keep the HT leads as the connectors will be needed. The VR sensor is usually mounted on the bell housing somewhere, depending on the engine.

When fitting the wheel set the engine to Top Dead Centre (TDC) if you fit the sensor so it aligns with tooth 9, as the following diagram, then you can use the Trigger Wheel settings in the diagram, this is recommended for ease of setting up.

Set the Trigger Return Value to 60deg and Spark Inverted Output = YES in the Spark Settings Menu.

Megasquirt hardware mods for 2 rotor rotary engines with the NipponDenso 2 tooth/24 tooth cam angle sensor:

1) Solder some jumper wire to U4 (opto-isolator) pin 6.

2) Solder some jumper wire to CPU pin 11

3) build a dual lm1815 or dual v3 vr conditioner circuit. (covered elsewhere).

4) Wire the output of one of the vr conditioners to the jumper wire soldered

to U4 pin 6, and wire the other VR sensor output through a 1k resistor to

the cpu pin 11 jumper wire.

5) Connect the 24 tooth VR sensor positive lead to the VR+ input of whichever

circuit is connected to U4 pin 6, connect the other VR sensor positive lead

to the other conditioner circuit.

At this point, we're ready to talk about VR sensor alignment, etc...

Since we're on a 4 cylinder/2 rotor engine, and we're using

a CAM angle sensor, which moves half the speed of the crank, we really have

what looks like a 12+1 wheel to the megasquirt. So what we want to do is

figure out what advance the engine likes when it's starting. For rotaries...

0, or even -5 degrees is good,

I think most 4 cylinders should work well with 10 deg. This will help us

determine our trigger angle:

We want our first trigger to be the tooth directly after the second wheel's tooth passes by the VR sensor; that tooth will be labled "tooth 1". For a rotary, we want a max advance of maybe 40 deg BTDC at high revs and low kPa, and we want a cranking angle of 0 degrees. On a 12 tooth wheel, each tooth represents 30 degrees of crank rotation. Since we want a maximum advance of 40 degrees, a good value for the trigger angle would be 50 degrees. However, if we count the next two teeth over, we get 20 degrees, and -10 degrees. This won't work for our cranking angle, so we set the trigger angle to 60 degrees BTDC, so the next two teeth are 30 degrees and 0 degrees.

With this configuration, in the wheel decoder settings you'd want the following settings:

Trigger A: 1 (60 deg BTDC)

Trigger A Return: 3 (0 Deg for rotor 1)

Trigger B: 7 (180 degrees from trigger 1, or 90 degrees on the cam angle

sensor, 60 deg btdc for rotor 2)

Trigger B Return: 9 (0 degrees for rotor 2).

In the Spark Settings menu, you'd set Trigger Angle to 60 degrees, Crank mode to Trigger return, and so that we can set the timing on our 13B rotary, set Fixed Angle to -5 (the location of the timing mark on the crank pulley).

You will have to wire your chosen ignitor to the megasquirt. Instructions to do this using LEDs can be found elsewhere.

Now it's time to get out the timing light, and stab the Cam angle sensor into the engine.

1) turn the engine over by hand and get the timing mark on

the crank pulley to line up... so we're setting the engine to -5 degrees

(5 ATDC).

2) turn the CAS (Crank/Cam Angle Sensor) so that tooth #3 on the 24 tooth

wheel lines up exactly with the VR sensor. Keep in mind that on this configuration,

there are 2 "tooth #3's," and either of them is fine.

3) now push the CAS into the engine, being careful to keep tooth 3 lined

up with the VR sensor. Once you get the CAS in, double check that it's lined

up.

4) Make sure your ignitor is hooked up, your CAS is hooked up to the vr

sensor conditioner you built, and make sure the megasquirt can output to

your ignitor/coil(s).

5) Assuming your car ran before you did all this, you should be able to

start the car now. You may want to test that the megasquirt is getting a

signal by seeing if TunerStudio displays rpms while cranking. I did this by

disconnecting the ignitor, then cranking.

6) Assuming your car started, and is now idling, and you're not using the

CLT/IAT advance/retard feature (Set it to OFF), you can set

the timing properly now using a timing light. Since you set the Fixed

Angle to -5, the the megasquirt thinks it's firing the sparks at 5 deg

ATDC, which is where the mark on the crank is for our engine (13B rotary).

hook up the timing light to the cyl 1 (or a leading coil wire for rotaries)

spark plug wire, and look at the timing. Adjust the CAS until the light

shows that the mark lines up the way it's supposed to... and your timing

is SET. Now what the megasquirt displays for timing really is the timing.

7) Go back to your megasquirt Spark settings, and set "Fixed Angle"

to "-10," which will cause the megasquirt to use the values

you entered into your spark map (you did do that right?).

Wheel Decoder TunerStudio Settings

Simple crank triggers such as 4-1 or 6-1 can also be used but the easiest way to get a wasted spark ignition setup from a distributor single coil setup is to fit a Ford 36-1 wheel onto the crank and use this code setting and directly drive a set of Ford coil packs. With this option you need to set up the "Wheel Decoder Settings", this means you need to know where the first missing tooth passes the sensor with respects to the timing, or what tooth the sensor is detecting when the timing is at TDC. We have designed this excel file to help you figure out the required settings, click on the image to download the file.

Please note the teeth are counted when

the ECU detects the first gap, (this gap is tooth Zero) the first tooth

on a -1 setup (or second gap on a 60-2 wheel) is tooth 1, etc. The last

tooth would therefore be 35 on a 36-1 or 59 on a 60-2. When using a wheel

with no missing teeth and a second trigger input the next tooth on the main

toothed wheel after the second trigger is defined as tooth 1. The

MS ECU can NOT trigger on a missing tooth, so you must ensure that all of

the used Trigger Position

Teeth as set in "Wheel Decoder Settings" are NOT set to ZERO,

if they are then you may have to alter the Trigger Angle a little

to select another tooth. However all of the UNUSED

Trigger Position Teeth MUST be set to ZERO!

Please also note that you can only use one tooth per trigger

position, so you CANNOT have the same number in

the Wheel Decoder Settings twice!!

Working examples:

Vehicle: Kia Rio

Engine: A6D 1.6L DOHC 16v 4cyl (A5D, 1.5L is identical setup wise)

Setup: 60-2 on flywheel, oem hall sensor in bellhousing

Trigger Angle: 67ΒΊ

Trigger Position A: 10

Trigger Return A: 18

Trigger Position B: 40

Trigger Return B: 48

2x VB921 IGBTs off LED17 and LED19, running dwell 4.0ms, cranking 6.0ms, on oem waste spark coils.

NOTE: Cyl 1,4 on LED19, Cyl 2,3 on LED17. Trigger angle actually corresponds to TDC Cyl 3

i suspect other Kia models to be the same, at least those

with the Siemens/Infineon ecu, which is a ripoff of the Bosch Motronic.

All the OEM sensors are "License Bosch" stamped right on them.

Thanks to sportage4x4

Car: Peugeot 405 1990

Engine: 1.9 litre, 4-cyl, 8 valve, XU9JAZ. appllies to any other XU5 or

XU9 (including the 16v) series running Motronic or Magneti Marelli (Solex)

G5, G6, 8P ECU. Older models fitted with dizzy cap delivering spark, later

ones with wasted spark.

Wheel type: 60-2 @ fly

Sensor type: OEM vr sensor

Wheel alignment: Tooth number 20 is under the sensor when engine is @ TDC

Wheel decoder setup:

Trigger A=10

Trigger B=40

Spark settings:

Trigger angle=60

Timebased cranking, advance 10 degrees

Coil: Peugeot 405 wasted spark coil (Facet aftermarket part)

Ignition module: Bosch 0 227 100 200 (Transpo aftermarket part)

Dwell settings:

4.0ms running dwell

8.0ms cranking dwell

1.0ms min. spark time

(dwell settings not scoped to optimum)

Thanks to tvh

1990 NA rx7 (s5 2nd gen)

1308cc

2 rotors

Trigger angle: 60 deg

Crank mode: Trigger Return

12 tooth wheel using 2nd trigger

Trig A: 1, Trig Return A: 3

Trig B: 7, Trig Return B: 9

Using the stock 2nd gen CAS as the wheel, with dual lm1815 vr sensor conditioner,

and using the stock 2nd gen leading and trailing coils with ignitors.

Using 2.6 ms dwell (stock ignitor increases this to a point based on RPM)

Thanks to muythaibxr

EDIS8 replacement - working on Rover V8

36-1 wheel aligned the same as EDIS8 (see EDIS)

Hand twisted pair cable from VR sensor to Megasquirt box routed well away

from plug leads.

trigger angle=60

Timebased cranking and 10deg cranking angle.

trig A=35

trig B=8

trig C=17

trig D=26

Four VB921 to drive the coils and set LED17,LED18,LED19,output3 all as spark

outputs.

Spark output "inverted"

Dwell control with 5ms cranking, 4ms running and a 0.1ms min discharge.

Be sure to use code 025i6 or newer.

EDIS6 replacement

36-1 wheel aligned the same as EDIS6 (see EDIS)

trigger angle=70

Timebased cranking and 10deg cranking angle.

trig A=35

trig B=11

trig C=23

Use three VB921 to drive the coils and set LED17,LED18,LED19 as spark outputs.

Spark output "inverted"

Dwell control with 5ms cranking, 4ms running and a 0.1ms min discharge.

EDIS4 replacement

36-1 wheel aligned the same as EDIS4 (see EDIS)

trigger angle=60

Timebased cranking and 10deg cranking angle.

trig A=3

trig B=21

Use two VB921 to drive the coils and set LED17,LED19 as spark outputs.

Spark output "inverted"

Dwell control with 5ms cranking, 4ms running and a 0.1ms min discharge.

Untested example

Euro Ford Granada/Sierra DOHC. Internal 36-1 wheel and single

coil / distributor

This assumes the 36-1 wheel aligned the same as EDIS4 (see EDIS pages)

trigger angle=60

Timebased cranking and 10deg cranking angle.

trig A=3

trig B=21

Use one VB921 to drive the coil and set LED17 as spark output (only 1 spark

out as only one coil).

Spark output "inverted"

Dwell control with 5ms cranking, 4ms running and a 0.1ms min discharge.

The MS ECU can NOT trigger on a missing tooth, so you must ensure that all of the used Trigger Position Teeth as set in "Wheel Decoder Settings" are NOT set to ZERO, if they are then you may have to alter the Trigger Angle a little to select another tooth. However all of the UNUSED Trigger Position Teeth MUST be set to ZERO!

The code acts as a front end ahead of the normal MegasquirtnSpark

system.

The first step the code takes is to find the missing tooth/teeth by comparing

the time between IRQ (Interupt Request) pulses (trigger inputs). The missing

tooth (-1 tooth) is found if the period is > 1.5* the previous, a -2

is found if the period is > 2.5* the previous.

Once the code has syncronised to the missing tooth/teeth it then counts

the other teeth. When the tooth number matches a predefined trigger position

it executes the rest of the code. The first tooth or the second missing

tooth detected after the first missing tooth is Tooth 1. The first missing

tooth is tooth Zero. A second set of trigger values can be used to define

"Trigger Return" positions that set the cranking timing.

The Trigger Return positions and the

Cranking Angle work together and it is VERY important to understand

how this works. It is usually set up for the cranking angle when there are

enough teeth. So if you have a 36-1 or 60-2, etc, set the Trig Return

tooth thats at 10deg BTDC, this is usually the firing angle at cranking.

So in the example below tooth 18 and 48 would be aligned with the sensor

at 12deg BTDC (this is as close as you can get to 10 on a 60-2). Next enter

12deg into the Cranking Angle, this is VERY important as it

is used to work out the Dwell! If your fitted the wheel your self then ensure

this angle is correct, if not alter it so it is, it may be 2-5deg out if

you fitted the wheel, so alter the value. This should be easy enough to

see or to work out using a timing light and crank the engine, if its sparking

at 8deg then enter 8, etc!

If you decide to not use Trigger Return (Timing Based) then set ALL

Trig Return pos to ZERO, equally if you dont have enough teeth to do

this (e.g. 4-1, 12-1, etc) set ALL the Trig Return Pos to ZERO and

set Timing Based in Cranking Timing

Example setup for COP with cam wheel and non-missing tooth crank wheel. The cam wheel must have a single trigger per 720 degrees of the crank (360deg of the cam). The crank wheel must have at least half as many teeth as the number of cylinders. i.e. 2 on a 4cyl.

Another COP example, this time an autronic wheel retrofitted

into a CAS (spins at cam speed). As this is a 4cyl there are four outer

holes. The single hole is the 2nd trigger "reset" pulse.

Second VR Sensor Input for Wheel Decoder

2 Sensors on Crank or Cam Sensor (with 2 pulses per cam rev) example -- 2nd Sensor on Cam (with 1 pulse per cam rev) example

The Second Input option is a variation of the multi-tooth or generic wheel for ignition timing input. Normally a multi-toothed wheel or generic has a missing or filled in tooth to provide a reference point. Where the timing wheel has all of its teeth, a second input every crankshaft revolution can provide the same timing capability as a missing or filled in tooth. The next tooth on the main toothed wheel after the second trigger is defined as tooth 1. All the other features and functions of the toothed wheel software is available, including wasted spark for distributor-less installations.

For some instances of Nippondenso electrical systems, (Mazda and Toyota) the second input allows the use of the OEM distributor, cam position sensors without having to mechanically modify anything. These distributors have a 24 tooth wheel which rotates at half crankshaft speed. Either a single second pickup and wheel with 2 teeth, or two pick-ups with a single tooth can be used as a second input into MSnS.

To use this feature you need to have an appropriate input signal conditioner for the main and second input, see the Second VR Sensor Input section HERE

The main wheel connection is made the same way as you would for any other wheel or main tachometer input, see the VR Sensor Input Section HERE

The second input is made with a duplicate conditioner and components to replicate the tachometer input but this is connected directly to Pin 11 of U1. Note as this pin is also an output in some configurations, it is strongly recommended you include a 1k resistor in series with Pin 11. This will protect both U1 and the VR conditioner from overloading each other if U1 Pin 11 is set as an output. A daughter-board will be required to mount these components with a flying wire soldered directly to Pin 11. (Underside of board)

Following Example

is when the Second Sensor is on the CAM or Crank with 2 pulse per cam revolution

(180deg apart) or 1 pulse on the Crank per revolution

(Primary sensor = Crank 60 teeth)

Ignition Options / Wheel Decoder and Output Pin Options - Ensure only the Wheel Decoder - Generic Wheel option is set. This example is for a 4cy wasted spark so it has ONLY Spark A and Spark B set! Please see the Basic Config manual for more.

If directly driving your coils from the MS ECU then set dwell as:

Please note that these will need to be tuned, see the Dwell section of this

manual.

Following Example

is when the Second Sensor is on the CAM with 1pulse per cam revolution:

(Primary sensor = Crank 60 teeth)

Ignition Options / Wheel Decoder and Output Pin Options - Ensure only the Wheel Decoder - Generic Wheel option is set. This example has Spark A, Spark B, Spark C and Spark D set! It could run a COP setup (4 cy) or a wasted spark 4cy. Please see the Basic Config manual for more.

| Primary teeth = 60 | Primary teeth = 4 |

If directly driving your coils from the MS ECU then set dwell as

:

Please note that these will need to be tuned, see the Dwell section of this

manual.

Finding Edis in North America -- Finding Edis in Europe -- Internal Mods to the MS ECU -- Edis Wiring Diagrams -- TunerStudio Settings

Fitting the VR Sensor and the 36-1 wheel

Ford's Electronic Distributorless Ignition System (EDIS) is an ignition system that does NOT require a cam position signal. It can function with just a variable reluctor crank position sensor (VR sensor) and a 36-1 tooth wheel (36-1 means '36 teeth minus one', and refers to 36 evenly spaced teeth, one of which has been removed).

Because it doesn't need a camshaft position sensor, EDIS is a particularly easy way to replace distributor ignitions when retrofitting older engines with a modern computer programmable ignition, but we now recommend directly driving the coil packs from the MS ECU using the VB921 FET's. This does away with the EDIS module, so all thats needed is the 36-1 wheel, a VR sensor and the coil packs. Please see the VR input Sensor wiring and the Direct Coil Drive Wiring section.

If you alread have an EDIS setup and want to use it then these are the mods for it:

The EDIS system is made up of:

EDIS module,

crank wheel,

crank variable reluctor sensor (VRS), and

one or more coil pack(s).

Finding Edis 4 in North America:

Early to mid 1990s Ford Escort/ Mercury Tracer with base 1.9L SOHC engine were fitted with the EDIS4 system. You can tell the engine because it has a tubular aluminium (NOT cast) inlet manifold.

The EDIS4 module is mounted just behind the fuse box on the drivers side of the engine bay, it has a label on the plug that says EDIS4. The bolts are 10mm AF. You are advised to remove the fuse box first for easier access. Cut off as much as the harness as you can.

Looking toward the passenger side end of the engine, the VR sensor is above and to the left of the end of the crankshaft. The easiest way to access the sensor is to remove the front wheel (if it's not already removed), lie on your back, and reach up from the bottom to access the sensor mounting bolts. The bolts are either small metric or star bit. Once it's off, the cable is most easily cut from the top.

The crank pulley bolt is 19mm. You will need to stop engine

from turning, various methods have been suggested. 1) remove the head, put

some rocks into the bore and refit the head. 2) remove a spark plug and

put a long bar down the hole 3) remove a plug from cylinder with piston

at BTDC and coil in some rope, remove rope when finished.

Click on images for a larger picture

Click on images for a larger picture

1a) EDIS4 module

1989-1993 Fiesta XR2i 1.6

1990-1992 Fiesta RS turbo

1989-1994 Escort 1.6i

1990-1994 Orion 1.6i

Modules are all in the engine bay and typically located in the middle of

the bulkhead or the right hand side as you face the car.

Known part numbers are: 89FB-12K072-AC, 91AB-12K072-AA

Orion CVH MPI

Orion CVH MPI  Fiesta / crossflow Escort

Fiesta / crossflow Escort  Mondeo with 1800/2000 engine.

Mondeo with 1800/2000 engine.

Location of the VR sensor varies. On the small CVH engines

it pokes through the rear flange of the engine towards the flywheel. 1.8CVH

Sierra has one on the front. 2.0DOHC Sierra/ Granada is in the block at

the left side way below the inlet manifold. Duratec V6 (Mondeo) is mounted

near the front, it also has a cam sensor that works too.

The mounting bolts are either small metric or star bit.

Escort / Fiesta location on engine flange above starter.

Escort / Fiesta location on engine flange above starter.

Do not confuse with the ESC II hybrid module which has a vacuum

tube and comes on the carb model cars.

There is also an aluminium one to avoid as well.

Click to enlarge picture of plastic hybrid module to avoid.

Click to enlarge picture of plastic hybrid module to avoid.

1b) EDIS6 module

up to 1995ish Mondeo V6 automatic

Ford/Cosworth Granada Scorpio 24v V6

Module located rear left of engine bay as you face the car.

Known part numbers are: 90GB-12K072-AB

1c) EDIS8 module

Chances of finding one of these in a scrapyard are very low! Not known to

have been installed on any European built vehicles. Your best bet is either

to import a module from the USA or buy new. I would suggest buying the other

bits locally.

For connectors try one off another car if all the wires are in use or one

off an ESC module. The number of wires used in the connector varies so check

they are all there!

There is a possibility of using 2 EDIS4 modules to drive a V8. But now that

the MS ECU can directly drive 4 coils (V8 in wasted spark) this is no longer

necassary.

2) 36-1 trigger disc

The 1.8CVH Sierra has a useful disc pressed onto the back of the crank pulley

All of the other CVH installs have the trigger teeth cut into the flywheel

and so are useless.

For a scrap yard trigger disc, remove from 1.8CVH Sierra.

You will need to stop engine from turning, various methods have been suggested.

1) remove the head, put some old bolts or other junk into the bore and refit

the head.

2) remove a spark plug and put a long bar down the hole

3) remove a plug from cylinder with piston at BTDC and coil in some rope,

remove rope when finished

4) Jam something into the flywheel teeth

Sierra pulley/trigger assy and VR sensor

Sierra pulley/trigger assy and VR sensor

If you are after a pressed steel disc, try part no. 1078767,

about £12 from Ford, this came on the 16v DOHC Granada engines, alternatively

wheels are available to order from HERE

3) VR sensor

Usually it is easiest to get from the same vehicle as the EDIS module so

the loom wiring colours match.

Or any vehicle with a trigger disc will yield one, so CVH Fiesta/Escort/Orion

or Fiesta with Valentia (crossflow) engine with ESCII hybrid, DOHC Sierra/Granada,

Mondeo. See HERE for more on VR sensors.

4) Coil pack/s

Usually it is easiest to get from the same vehicle as the EDIS module so

the loom wiring colours match.

Also CVH Fiesta/Escort/Orion/Sierra or Fiesta with Valentia (crossflow)

engine with ESCII hybrid, Zetec e.g. Mondeo.

These 4cyl engines have 4 post coils. The V6 Mondeo has a 6 post coil. 8cyl

applications use two 4 post coils.

Carb Fiesta Valentia engines have the coil pack on the rear of the block.

Mondeo Zetec have the coil pack beside the rocker cover. The HT leads are

usually very short, but the ends can be removed with some lubricant and

re-used on new leads by re-crimping them with a pair of pliers. It can be

handy to get 2 sets so you can practice a little first.

Input Mods for V3.0 PCB:

Output mods for V3.0 PCB:

V2.2 PCB ONLY

Edis Wiring for a V3.0PCB:

Edis Wiring for a V2.2 PCB:

Ensure that the ONLY ignition option in Ignition Options / Wheel Decoder and Output Pin Options is EDIS and that LED17 is set as SparkA, NO other outputs must be set as a Spark Output.

Fitting the VR Sensor and the 36-1 wheel

Assuming you have obtained a suitable 36-1 wheel, you need

to establish the correct relationship between the VR sensor and disc.

There are two methods to visualise the relationship with the same outcome.

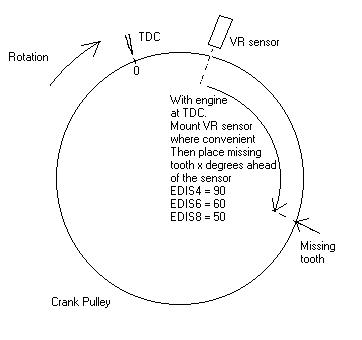

SPECIFIC-ANGLE is defined as follows: EDIS4=90, EDIS6=60, EDIS8=50

EITHER

1) Turn your engine to SPECIFIC-ANGLE degrees before TDC (check direction

of rotation!). Mount the VR sensor wherever is convenient and mount trigger

disc so that the centre of the sensor aligns with the centre of the missing

tooth.

OR

2) Set your engine at TDC, then put the missing tooth either 9, 6 or 5 (depending

on no. cylinders) teeth in front of the sensor. (Count from missing tooth

in opposite direction of rotation) This will put the centre of a tooth

central to the sensor.

i.e. EDIS4 = 9 teeth, EDIS6 = 6 teeth, EDIS8 = 5 teeth (Ensure you know the direction of rotation for your engine)

Direction of rotation for this example is Anti-Clockwise

for below

Direction of rotation for this example is Clockwise for below

There should be 0.75 - 1.0mm gap between sensor and wheel.

To test this alignment it is best to run the EDIS in limp home mode. This can be achieved by disconnecting the SAW plug/socket or switching off/unplugging the ECU. Fit your strobe onto no.1 plug lead as normal (you may need to try the other tower of the pair). Ensure EDIS still has power and crank your engine, check that the timing is exactly 10deg. If not, adjust your sensor until it is. It is safe to idle the engine with the SAW lead disconnected, timing should be rock solid at 10BTDC. Don't forget to reconnect the plug when done!

Optional: multi-spark mode

NOTE: Multi-spark is currently under test with MSnS-extra firmware.

1) First get your engine running with multispark off, then:

2) Go to the Advanced >Advanced code options and set EDIS multispark

on. Turn megasquirt off then on.

2) Check your timing with a strobe at low rpm (less than 1100.)

3) If the timing is locked to 10BTDC then the module is not compatible.

4) If the timing varies as expected (you can use Fixed on Spark>Spark

Settings to set e.g. 5 or 15) then it is compatible.

5) If in doubt leave it switched off.

6) Advanced tester can experiment with the max rpm. The patent states 1100rpm.

Ford Thick Film Integrated IV Ignition Systems (TFI)

MS Input Wiring -- MS Output Wiring -- TFI Schematic -- TunerStudio Settings

The code is only designed for "push start" modules which are claimed to be grey in colour. Computer controlled dwell modules are black. Maybe this is USA only data because the Push Start module I used is mainly black. On a push start the START wire will run to the ignition switch. On a CCD that pin is IDM and will run to the ECU.

ALPHA testers desired for CCD modules. Try as below but set to dwell control instead of 50% duty.

Here is the pinout of a typical dizzy mounted module, consult you Haynes manual if necessary.

My suggestion to users is to get your car running fuel only before throwing timing into the mix. The TFI dizzy has a limp home 10deg mode so if the SPOUT wire is left unplugged it will continue to spark just fine. This way you will prove that you can idle with Megasquirt before adding timing control.

Board Mods - input side

The input side on the MS board is fairly straightforward, most boards will

need no changes.

For all boards you connect the TFI PIP wire to the Megasquirt TACH input

which is DB37 pin 24.

Input Mods: See also the TFI Output mods drawings HERE

V3.0 PCB ONLY:

V2.2 PCB ONLY:

NOTE!! If you are using an aftermarket spark box like

MSD you can skip the special circuit and use a regular "LED17"

spark output. See the MSD Output Wiring under HERE.

If you do this you must also configure your spark type as MSnS and NOT

TFI in Codebase and Output Functions!!!

When the code is set to TFI it expects you to use the TFI module to fire

the coil and provide cranking spark.

When using the TFI module to drive the coil carry out the following: (NOT for an MSD)

V3.0 PCB ONLY:

V2.2 PCB ONLY:

Set the Codebase and Outputs page as follows:

Set the Trigger Angle to 10 degrees and spark output

inverted to Yes.

Set the Dwell to:

For more technical details of the Ford TFI system please see this document HERE.

There were a number of different kinds of General Motors HEI modules:

* 4 pin module - electronic ignition, but doesn't

do computer timing control, top left

* 7 pin module (large) - electronic module that does timing control,

used with coil-in-cap distributors, top right

* 7 pin module (small) - electronic module that does timing control,

used with some external coil distributors, bottom right

* 8 pin module - electronic module that does timing control, used

with most V8 external coil distributors, bottom left

* 5 pin module - rare and not discussed here. not shown

Internal Mods for V3.0 PCB's

HEI7/8 mode will use the Opto/Hall input, so the VR components

are not required.

Internal Mods for V2.2 PCB's

Wiring the HEI module:

In Ignition Options / Wheel Decoder and Output Pin Options set the HEI Ignition option, set LED17 as SparkA out and LED19 as Spark B output.

In Spark Settings ensure "Trigger Angle" is set to 10 deg and Inverted Spark Output = NO.

Set the dwell to:

GM DIS Wiring -- Saturn 1.9L DIS Wiring -- North Star Wiring

Most of the following explanation comes from "WopOnTour" - many thanks!! Please read his full description HERE

4cyl and 6cyl engines are essentially identical schematic. The only difference is the 3X shown (toggles voltage every 60 degrees) becomes a 2X (60/120) as the and the 4cyl DIS coil will toggle the reference voltage on every 3rd 60 degree increment (180 degrees)

NOTE: This will NOT work for 2005 3.5L HV-V6 using the new "quick start" DIS (or any other up-integrated DIS that does not use a "Bypass" circuit) I also have concerns on the 87-88 VIN-D Quad 4 engine that (for whatever reason) has the 7X reluctor notches machined at TDC. So you may need to eliminate Bypass altogether and run "cranking EST"

ALSO NOTE: Depending on the DIS module used you MAY have to bypass the Opto coupler within the MS directly connecting the IGN REF input at pin 24 to the opto output.

V3.0 PCB mods:

V2.2 PCB mods:

Thumb nails, click to enlarge.

Thumb nails, click to enlarge.

*Note: The injection events shown every 120 degrees is just for startup on the stock GM ECM, after 400 rpm is achieved the simultaneous injection event occurs once per crankshaft revolution (or twice per cycle in MS terms)

Thumb

nails, click to enlarge.

Thumb

nails, click to enlarge.

You MAY want to make sure there is identical ground potential

between the MS and the DIS module by connecting Pin F of the DIS module

to the same engine ground point as your Megasquirt.

Wire the Megasquirt as the GM DIS wiring above, then wire the external as:

In Spark Settings ensure "Trigger Angle" is set to 45deg and the Trigger Angle Addition to +45 and Inverted Spark Output = YES or the advance will be about 120 degrees from desired. Then in Codebase and Output functions ensure LED17 is SparkA and LED19 is SparkB, set the Dwell to Fixed Duty - 50% Duty.

Noted that advanced displayed in TunerStudio DID NOT include approx 10 degrees of advance

Wire the Megasquirt as the GM DIS wiring above, then wire the external as:

In Spark Settings ensure "Trigger Angle" is set to 45deg and the Trigger Angle Addition to +45 and Inverted Spark Output = YES or the advance will be about 120 degrees from desired. Then in Codebase and Output functions ensure LED17 is SparkA and LED19 is SparkB, set the Dwell to Fixed Duty - 50% Duty.

Noted that advanced displayed in TunerStudio DID NOT include

approx 10 degrees of advance

The 2 connector pinouts are as follows:

Connector 1 (C1)

PN#12084220 / 6-way but only 5 used

A- IGN+ (fused)

B- Not Connected

C- EST (timing signal from MS)

D- IGN REF (to MS TACH input)

E- Tach (Optional)

F- Bypass (5V applied by MS after engine start)

* I recommend you always put an inline connector in the Bypass circuit so

that you can easily drive the DIS to base timing fail-safe mode (Bypass)

Connector 2 (C2)

PN#12084415 / 5-way

A- CKP+

B- CKP-

C- CKP Shield (RF Gnd)

D- REF LO

E- GND

Note: It's not mandatory to use Saturn Parts here. You can optionally use the DIS module and connectors from another "MSnS-E Compatible 4 cyl Engine".

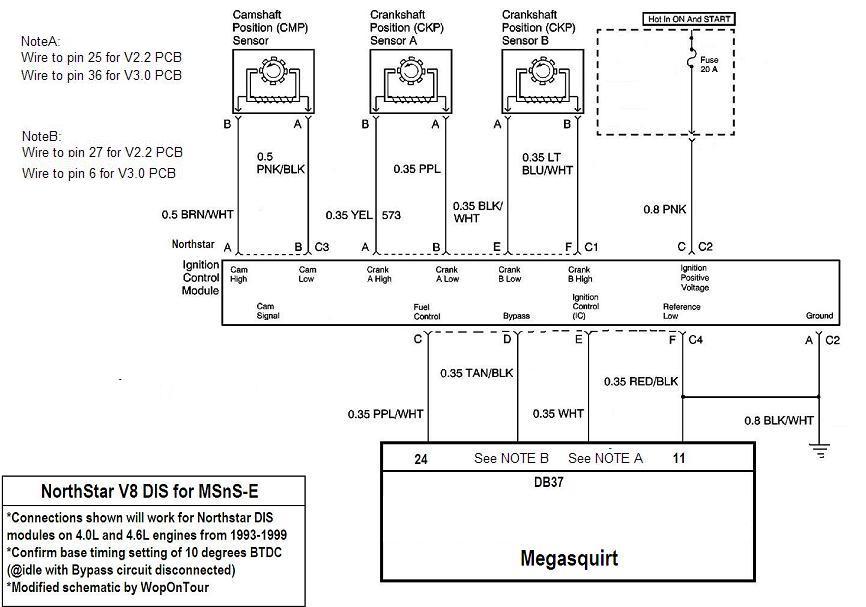

Should work for any Northstar WITHOUT coil on plug or on newer engines (not the VVT LH2) with the addition of an older DIS module and coil pack. THIS HAS NOT BEEN TESTED ON A RUNNING ENGINE YET SO THE TRIGGER ANGLES NECCESSARY TO GET 100% TIMING ACCURACY HAS YET TO BE CONFIRMED Below is the DIS waveform index for the Northstar and the DIS to MS wiring schematic

Buick Computer Controlled Coil Ignition (C3I)

Most of the following explanation comes from "WopOnTour"

- many thanks!!

I have been doing some extensive testing on the Buick 3800 Computer Controlled

Coil Ignition (C3I) system for MSnS-E (Fidle as spark control) using my

MS and a 2000 C3I mockup that I have. The scope waveforms and patterns look

very promising.Here's what I have learned so far (although keep in mind

this was done in a mock-up state only and NOT on a running engine)

NOTE: Depending on the C3I module used you MAY have to bypass the Opto coupler within the MS directly connecting the IGN REF input at pin 24 to the opto output. The best option is to post a thread on the MSEXTRA forum giving details of your setup before you start.

In order to potentially run the C3I ignition as used by the 3800 with MSnS-E you will need to REROUTE the following signals from the C3I module to the MS:

- connect the purple/white wire (C3I ignition module terminal D) to PIN24 of the DB37@Megasquirt. This C3I signal is commonly labeled "low resolution engine speed signal" is actually a digital 3X (ie transitioning every 120 degrees of crankshaft and) near identical to the old DIST REF but is synthesized by the C3I module from the 18X hall-effect input (18/6=3) *NOTE-This circuit was previously routed to the oe ECM.

- connect the "IC Timing signal" (aka 5V Bypass) which is the Tan/Black wire at terminal B of the C3I ignition module to pin 27@DB37 of Megasquirt. *NOTE-This circuit was previously routed to the oe ECM.

- Finally the Electronic Spark Timing (IC timing control) a white wire at pin A of the C3I ignition module to the reconfigured LED17 @ Pin25 at the Megasquirt DB37 connector. *NOTE-This circuit was previously routed to the oe ECM.

V3.0 PCB mods:

V2.2 PCB mods:

External Wiring for all MS PCB's:

Please Note: You MAY want to make sure there is identical ground potential between the MS and the C3I module by connecting Pin L of the C3I module to the same engine ground point as your Megasquirt.

MOST of the remaining connections at the C3I ignition module MUST REMAIN connected as factory. These include IGN+ (terminal P), Ground (terminal K) and the circuits to the various hall-effect sensors (terminals G,H,J,M and N) While all of these sensors are not necessary they do share a certain amount of circuitry (see schematic) and will facilitate future possible use of these signals (for possible enhancement through wheel decoding or maybe SFI on the MSII)

The following circuits at the C3I ignition module that can

be safely removed as they went to the OE ECM. (actually it's recommended

that these circuits just be either "clipped" at the ignition module

to maintain connector seal integrity or just insure they are properluy "dead-ended")

So you can safely "clip the wires to IGN MODULE terminals

C (Medium Resolution Engine Speed Signal)

F (Camshaft Position Signal) and

L (low reference)

*The wire at E can also be clipped as AFAIK was never used anywhere.

This should work for any Buick 3800 from 1988 to present

In Spark Settings ensure "Trigger Angle" is set to 70deg.

Codebase and Output functions ensure LED17 is SparkA and LED19 is SparkB, set the Dwell to Fixed Duty - 50% Duty

5 Cylinder Engines (Audi, etc)

For distributor based engines then this is a straight forward MSnS setup see HERE, but for COP setups you will need 2 trigger inputs. Whilst it is possible to do it with a cam sensor, it is easiest to do it with 2 sensors, one on the crank and the other driven off the cam. The first sensor off the crank needs to be at least 5 teeth equally spaced, a 60-2 wheel would be best and shouldn't be too hard as most Audi's use these anyhow. The second sensor needs to pick up 1 pulse per cam revolution. This would need a second sensor input circuit wired to Pin11 of U1, the circuit would depend on the type of sensor used, but all circuits will need the opto-isolator between the sensor and Pin11 of U1. See HERE

Twin Cam 4G63 and 4G9

powered DSM (Eclipse / Talon / Lazer)

Double Over Head Cam engines (DOHC)

V2.2 wiring mods -- V3.0 wiring mods -- External wiring diagram -- TunerStudio Settings

These instructions are based on information from Jerry at

DIYAutoTune.com and from Zainal

Hasnan, many thanks to both of them.

This is for 1st gen DSM with the 4G63 engine as well as the 4G9 series engine:

4G91 DOHC = 1.5 liter

4G92 DOHC = 1.6 liter

4G93 DOHC = 1.8 liter

There are two 'sets' or 'rings' of holes in the optical CAS. The outer ring

of holes is read by an optical sensor and then sent to the ECU, this is

referred to as the CKP signal. Likewise the inner ring with only

one hole is also read by an optical sensor, sent to the ECU and is referred

to as the CMP signal.

Outer Ring - Crank Angle Sensor (RPM) - CKP

Inner Ring - Top Dead Center Sensor - CMP

The theory here is to drive the CKP as the main trigger input (pin24 of the db37) and the CMP as the second trigger input (pin11 of U1).

You should be able to swap the 1G DSM 4G63 CAS assembly into

the 2G DSM 4G63 and use these instructions as well. If not see the SOHC

instructions HERE

For the CMP trigger input (Inner ring):

For the CKP trigger input (Outer ring):

V2.2 output wiring mods:

(the following mods will trigger the stock ignitors. It is felt that

it is easier to get running using the original ignitors so this is the recommended

and tested method. But if you want to drive the coils directly rather than

through the ignitors then please see the Direct Drive

section, the Spark Inverted will then = YES!)

For the CMP trigger input:

For the CKP sensor input:

V3.0 PCB Output wiring MODS:

(the following mods will trigger the stock ignitors. It is felt that

it is easier to get running using the original ignitors so this is the recommended

and tested method. But if you want to drive the coils directly rather than

through the ignitors then please see the Direct Drive

section, the Spark Inverted will then = YES!)

External wiring diagram for 4G63 all board versions:

Settings for 4G63 all board versions:

(Please note: The Trigger Angle setting will need adjusting more accurately

using a strobe and a Fixed Angle see HERE)

(It is felt that it is easier to get running using the original ignitors

so this is the recommended and tested method. But if you want to drive the

coils directly rather than through the ignitors then please see the Direct

Drive section, the Spark Inverted will then = YES!)

Mitsubishi and Proton distributor based engines, Single Over Head Cam (SOHC)

V2.2 wiring mods -- V3.0 wiring mods -- External wiring diagram -- TunerStudio Settings

Thanks to Zainal Hasnan for the following information and

pictures.

The SOHC usually runs a distributor. These engine types are:

Mitsubishi and Proton NA (They share the same engines)

4G13 1.3 liter sohc injection.

4G15 1.5 liter sohc injection

4G92 1.6 liter sohc injection

4G63 2.0 liter sohc injection

There are 2 types of distributor that runs these engines:

| Vanes type sensor. |

Windows type sensor

|

However, they only have 1 inner windows or vane for the tdc sensor.

To run these without modifying it to the same spec as the 4G63 then it is best to use MSnS mode using the outer (4 vaned) sensor and keep the distributor.

V2.2 output wiring mods:

(the following mods will trigger the stock ignitors. It is felt that

it is easier to get running using the original ignitors so this is the recommended

and tested method. But if you want to drive the coils directly rather than

through the ignitors then please see the Direct Drive

section, the Spark Inverted will then = YES!)

V3.0 PCB Output wiring MODS:

(the following mods will trigger the stock ignitors. It is felt that

it is easier to get running using the original ignitors so this is the recommended

and tested method. But if you want to drive the coils directly rather than

through the ignitors then please see the Direct Drive

section, the Spark Inverted will then = YES!)

External wiring diagram for SOHC distributor based 4G63 all board versions:

TunerStudio Settings for SOHC distributor based 4G63 engines

(Please note: The Trigger Angle setting will need adjusting

more accurately using a strobe and a Fixed Angle see HERE)

(It is felt that it is easier to get running using the original ignitors

so this is the recommended and tested method. But if you want to drive the

coils directly rather than through the ignitors then please see the Direct

Drive section, the Spark Inverted will then = YES!)

Mods for a 2 Rotor Mazda engine -- Mods for a 3 Rotor Mazda engine

The rotary engine is obviously fundementally different

to a normal 4 stroke engine, but it can still be controlled by the MS ECU

running the MS1 Extra code as long as a few rules are followed. With a four

stroke engine, in 720° of crank rotation it will draw in the equivalent

amount of air as its rated displacement. But with a rotary engine in the

same 720° it draws in twice its rated displacement.

Therefore:

If you have a 2 rotor (Mazda 13B) engine (1.3 L) it's really like a 2.6L

4 cyl 4 stroke engine.

If you have a 3 rotor (Mazda 20B) engine (2.0L) , it's really like a 4L

6 cyl 4 stroke engine.

The rotary engine has a leading and a trailing ignition (2 plugs per rotor) the leading fires first then the trailing fires a few degrees later. On a 2 rotor engine the leading can be fired in a wasted spark format, but on a 3 rotor engine the leading must be driven by 3 individual coils e.g. COP. Simply set the system up as a 6 cylinder engine running wasted spark, this will fire the 3 spark outputs (Spark A, B and C) every 360 deg of crank rotation. Please see the Rotary Trailing Setup HERE for more info before running your engine. For more setting details on the rotary engines please see HERE.

2 Rotor Mazda Engine (13b 1.3L) wiring diagrams:

In order to use the BAC valve please see the hardware mods for the Idle valve HERE.

V2.2 PCB internal mods:

Input mods:

The MS V2.2 ECU will need to have 2 VR conditioners (LM1815), the following circuit contains two (LM1815):

This circuit's connections assume that the pcb will be mounted internally (inside the MS ECU's case) This can be mounted externally but the connections for Ne+ and G+ would connect directly to the conditioner rather than via the db37 connector.

|

DigiKey part

numbers:

|

Farnell

part numbers

|

|

1K resistor = 1.0KQBK-ND |

1K resistor = 509-164 |

Please note: Above part numbers will need checking, some components will come with a minimum order in multiples of 5 and 10.

If fitting the above circuit external to the MS ECU then

the Ne+ wire (24 tooth VR sensor positive lead) and the G+ wire (2 tooth

VR sensor positive lead) on the CAS need to be wired directly to the above

circuit:

NoteA : Connect to Ne+ wire.

NoteB: Connect to G+ wire

The VR sensor's grounds should ALL be grounded back to the board with the

lm1815 on it.

The output of U1 (above) on pin 12 should be wired to pin 6 of U4 on the megasquirt board. U4 is a six pin chip on the MS ECU board, the opto-isolator, this uses the output transistor within the opto as an inverter. The output of U2 (above) should be wired through a 1k resistor to pin 11 on the CPU.

Output Mods for V2.2 PCB:

External wiring for V2.2 PCB:

V3.0 PCB internal mods:

As the V3.0 PCB already has a built in VR conditioner then there's only the need to build one extra conditioner for the 2 toothed CAS signal. The following diagrams assume the conditioner will be mounted inside the MS ECU case.

|

DigiKey part

numbers:

|

Farnell

part numbers

|

|

1K resistor = 1.0KQBK-ND |

1K resistor = 509-164 |

Please note: Above part numbers will need checking, some components will come with a minimum order in multiples of 5 and 10.

You need to connect the output of the LM1815 (Pin 12) straight to U1 pin 11 via a 1K resistor.

Wire the MS internally for a VR input, link TSEL to VROUTINV and link VRIN to TACHSELECT:

V3.0 PCB Output wiring:

External wiring for V3.0 PCB:

3 Rotor Mazda Engine (20B 2.0L) wiring diagrams:

I need some help here, anyone

done a 3 rotor they can give me the info for ?

If so please email me philip.ringwood(at)ntlworld.com

V3.0 Mods -- V2.2 Mods -- External Diagram -- TunerStudio Settings

Input Mods:

Output mods:

Input Mods:

Output Mods:

Toyota VAST External Drawings:

Trigger Input Wiring Diagrams:

Wiring for V3.0 PCB -- Wiring for a V2.2 PCB

How you should connect a Hall sensor to the MS ECU all depends on what comes out of the Hall sensor.

Turn the engine until cylinder 1 should fire. Turn the distributor until the rotor point to the contact for cylinder 1 in the distributor cap.

Make sure one of the metal finger edges are close to the Hall sensor, either going in or out will be fine.

Turn the engine backwards until the edge is well out of the Hall sensor. Measure the output voltage from the Hall sensor Turn the engine forward until the edge has passed through the Hall sensor. Measure the output voltage.

High to low. For Hall Sensors that are Hi (+5V to 12V) when there is no tooth infront of the sensor and Lo (Gnd) when the edge of the tooth is infront of the sensor:

Low to High. For Hall Sensors that are Low (Gnd) when there is no tooth infront of the sensor and Hi (+5 to +12V) when the edge of the tooth is infront of the sensor

(This appears to be the most commonly used sensor from what I understand, so if in doubt try this one first)

Hall or Optical input sensor wiring for V2.2 PCB

How you should connect a Hall sensor to the MS ECU all depends on what comes out of the Hall sensor.

Turn the engine until cylinder 1 should fire. Turn the distributor until the rotor point to the contact for cylinder 1 in the distributor cap.

Make sure one of the metal finger edges are close to the Hall sensor, either going in or out will be fine.

Turn the engine backwards until the edge is well out of the Hall sensor. Measure the output voltage from the Hall sensor Turn the engine forward until the edge has passed through the Hall sensor. Measure the output voltage.

Hi to Lo. For Hall Sensors that are Hi (+5V to 12V) when there is no tooth infront of the sensor and Lo (Gnd) when the edge of the tooth is infront of the sensor :

Lo to Hi. For Hall Sensors that are low

(Gnd) when there is no tooth infront of the sensor and Hi (+5 to +12V) when

the edge of the tooth is infront of the sensor

When hall sensor output is 5V use:

Lo to Hi. For Hall Sensors that are low (Gnd) when there is

no tooth infront of the sensor and Hi (+5 to +12V) when the edge of the

tooth is infront of the sensor

When hall sensor output is 12V use:

V3.0 PCB Wiring -- V2.2 PCB Wiring

Example of a Ford Variable Reluctance Sensor (VR Sensor), these are positioned so they detect the teeth on a crank wheel. When the edge of a tooth (piece of ferrous metal) passes them at high speed and at a very close proximity (Gap of 0.75 - 1.0mm) they generate a small signal.

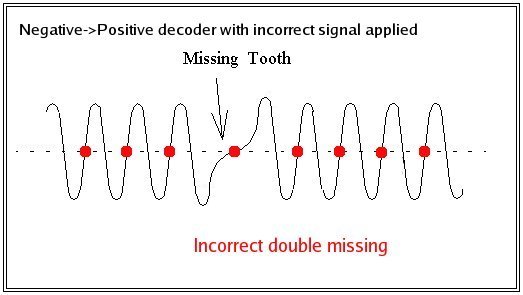

The following diagram shows what happens when the VR jumpers

on the V3.0 PCB or the VR sensor is wired incorrectly:

(VR sensor ground signal wired to pin24, the sensors signal +ve wired to

the screen and the VROUTINV linked to TSEL)

or

(VR sensors +ve signal wired to pin24 , the sensors ground wired to the

screen and the VROUT linked to TSEL).

The trigger points (where the signal goes through the line on the positive

going slope) are shown in red. The time between the trigger points is consistant

untill the missing tooth comes passed the sensor. The gap has increased

a little (not fully) as the wave returns to the line but as it has to wait

untill the next positively going slope the next gap is also decoded as another

missing tooth.

This diagram shows the jumpers and the VR sensor wired correctly;

(VR sensor +ve signal wired to pin24, the sensors ground wired to the screen

and the VROUTINV linked to TSEL)

or

(VR sensor ground signal wired to pin24 , the sensors +ve wired to ground

and the VROUT linked to TSEL).

This time the negative side of the slope is used as the trigger edge. This

means that as the missing tooth passes the sensor it doesnt trigger the

ECU untill the fall from the next tooth (Tooth 1).

VR Sensor Wiring for a V3.0 PCB

Adjust both the pots fully counter-clockwise (ccw) as a starting point, they don't physically stop turning, you will hear them click when they are fully one way. Generally the pots end up either fully ccw or a few turns clockwise from there.

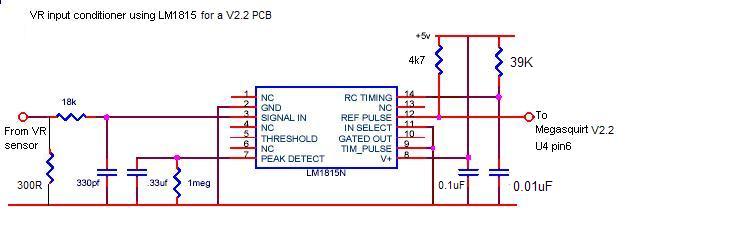

VR input Sensor wiring for a V2.2 PCB

V2.2

PCB ONLY

V2.2

PCB ONLY

|

DigiKey part

numbers:

|

Farnell

part numbers

|

|

300R resistor = 330QBK-ND |

300R resistor = 543-251 |

Please note: Above part numbers will need checking, some components will come with a minimum order in multiples of 5 and 10.

Second VR Sensor Input for a V2.2 and V3.0 PCB's

This is the same circuit for a V2.2 and a V3.0 PCB when adding a second Variable Reluctor (VR) sensor. Another option is to build the VR conditioner from the V3.0 PCB. If you are using a second Hall sensor input then see HERE

|

DigiKey part

numbers:

|

Farnell

part numbers

|

|

1K resistor = 1.0KQBK-ND |

1K resistor = 509-164 |

Please note: Above part numbers will need checking, some components will come with a minimum order in multiples of 5 and 10.

Second Trigger Input for V2.2 and V3.0 PCB's

Many Mazda and Toyota engines utilise Nippondenso ignition

which uses a dual wheel crank angle sensor (CAS) which has one 24 tooth

wheel and a 2 or single tooth second wheel. This is also needed to run a

5cylinder engine in COP mode it can also be used inventively to give 4 cyl

COP or could be used with the dual pickup crank trigger from SDS for 4cyl

wasted spark. For setting up TunerStudio see HERE

.

If using a VR sensor then see the Second VR Sensor Input section for your

pcb version.

Depending on what sensor you have depends on the input stage, but all sensors will need an opto isolator setup like this unless your using the VR conditioner circuit.

|

DigiKey part

numbers:

|

Farnell

part numbers

|

|

1K resistor = 1.0KQBK-ND |

1K resistor = 509-164 |

Please note: Above part numbers will need checking, some components will come with a minimum order in multiples of 5 and 10.

Eliminating Cross Talk and Wiring Considerations for VR Sensors

Each of these VR conditioners is a very high input impedance amplifier. The VR voltages may be reasonably high and the insulation thin or there may even be a common wire for more than one sensor. Where this occurs, cross talk may result in the signals due to capacitive or inductive coupling, Fortunately, the resistance and hence impedance of the VR coils may be quite low and they can produce reasonable signals into low impedance loads. Ensure you use a screened cable for te VR sensor's signal from the sensor all the way to the MS ECU,(2 core audio phono cable is sufficient) ground the screened core only at the end of the ECU (e.g. pin 7 or 8 of the DB37), leave the sensor end of the screen insulated.

The signal below is a the output of 2 VR conditioners, one from each of the generic wheel (blue) and the second input (red). The cross talk is very noticeable and caused misfiring.

Tweaking the input resistor values as per the earlier version

of the V3 VR conditioners in the circuits above, results in a much cleaner

signal as shown below.

Using the pots can assist in setting the values of the load resistor, along with a bench testing facility for the VR sensors and trigger wheel. An Oscilloscope (or an adapter for the sound card of your PC with suitable software (eg Creative Wave Studio)) can greatly assist in fine tuning the input load resistors. Getting a good clean signal into MS is essential or you will spend hours trying to track down problems later on.

Luminition Optical Input for a V3.0 PCB

NB. If using luminition (MSnS Mode) you will have to rephase

your dizzy so that the trigger happens at say 60BTDC but the rotor is pointing

to a tower at 20BTDC.

Luminition Optical Input for a V2.2 PCB

NB. If using luminition (MSnS mode) you will have to rephase

your dizzy so that the trigger happens at say 60BTDC but the rotor is pointing

to a tower at 20BTDC.

Distributor points input for a V3.0 PCB

NB. If using points (MSnS mode) you will have to rephase your

dizzy so that the trigger happens at say 60BTDC but the rotor is pointing

to a tower at 20BTDC.

Distributor points input for a V2.2 PCB

NB. If using points (MSnS mode) you will have to rephase your

dizzy so that the trigger happens at say 60BTDC but the rotor is pointing

to a tower at 20BTDC.

Spark Output Wiring Diagrams.

MSD output wiring diagram for a V3.0 PCB

Set Spark Inverted = YES in Spark Settings and Dwell Duty to Fix - 50% and LED17(D14) to SparkA output in Codebase and Output Functions.

V3.0

PCB

V3.0

PCB

MSD output wiring diagram for a V2.2 PCB

Set Spark Inverted = YES in Spark Settings and Dwell Duty to Fix - 50% and LED17(D14) to SparkA output in Codebase and Output Functions.

V2.2

PCB ONLY

V3.0 PCB Wiring -- V2.2 PCB Wiring -- External Wiring all versions -- TunerStudio Settings

Please note this is no longer the prefered method, the

Direct drive method is prefered. See HERE for

V2.2 or HERE for V3.0

The Bosch module 0 227 100 137 / 0 227 100 139 is designed to be used with

Hall effect and also takes care of the coil dwell period. The module trigger

when pin 6 is grounded, but the dwell control prevents it sparking on the

first trigger.

Pin 1 > (-) side of coil (is labelled "1" on

the coil)

Pin 2 > Good Ground

Pin 3 > not used

Pin 4 > Switched 12v* (eg from (+)side of coil, labelled "15"

on the coil)

Pin 5 > not used

Pin 6 > Spark output from Megasquirt (Pin 36 for a V3.0 PCB or pin 25

(X11) for a V2.2 PCB)

Pin 7 > not used. Not always present.

*source needs to supply a constant 12v when the ignition is

switched to "on"

If you use this module make sure you get the coil too. Normally there

should be a label on the coil saying it is for use in transistorized ignitions.

If you are getting this part from the junkyard, be sure to check that you

have the correct wiring pigtail - later (like early 1990s) pigtails have

only 4 wires - you need the connector with 6 wires.

See HERE for a list of suitable modules, etc.

Bosch Ignition Module Wiring for a V3.0 PCB

Bosch Ignition Module Wiring for a V2.2 PCB

Bosch Ignition External Wiring for all versions

In TunerStudio set the Codebase and Output Functions as:

Single Coil Direct Drive Output for a V3.0 PCB

These instructions are only suitable for single and twin spark outputs, for more than 2 sparks see the mutiple output section

Very Important: Set Spark Out Inverted = YES and set the Dwell to around 6.0mS for cranking 3.5mS for Running and 0.1mS for the Minimum Time as a starting point! Also set LED17 as SparkA output in Output Pin Options!! Read the Software manual for more info!!

Single Coil Direct Drive Output for a V2.2 PCB

It is recommended that V2.2 users fit a 15 or 25 pin db connector onto the case of the MS ECU. The reason is that the spare connectors on the V2.2 are not really capable of driving the current required for a coil unless you double them up (e.g. X11 and X12 as the ground X13 and X14 as the source). This is only suitable for a single VB921, if running more than one then see HERE.