I have a throttle body that has a built in 4 wire IAC, I'd really like to use it. No direct plug and play with the microsquirt.

Retrofitting a TRX700XX throttle body onto an XR650L for a fuel injection conversion. It's 95% theory at this point, the bike is torn down for a full rebuild and ground up reinforcement and modification.

I read through the whole Idle Air section of the Megasquirt Manual (found here ).

If we've figured this out later, and your reading it then, and you don't know how a stepper motor works, check this out:

http://www.freescale.com/files/microcon ... AN2974.pdf

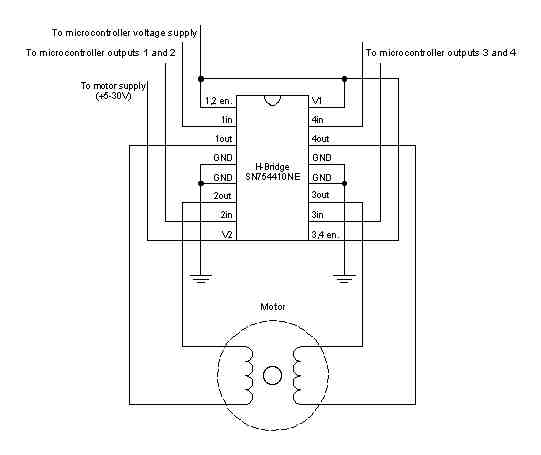

So, I've been dragging around the internet trying to find a way to turn the PWM signal into a 4-wire signal to operate basic H-bridge circuits that I "believe" the megasquirt boards would already have, but microsquirt does not (to save room?).

So I was thinking how do I translate PWM signal into something a little more usable. I googled my face off till I found this. All it needs is my PWM signal, 12vdc and a ground, and it will give me a variable 0-5vdc, sounds good to me!

Control an LM317T with a PWM signal

Now I have a 0-5vdc signal, it sounds more usable, but still not quite there yet...

I need to take that signal and turn it into something I can control those H-Bridge circuits with.

I found this which may solve another part of my predicament:

Adafruit Trinket - Mini Microcontroller - 5V Logic

Little bit of of code writing and a few beers and I think It could be used to translate a 0-5v signal to the 4 wire analog I need.

I know I'd need to take the signals from the above and step them up to whatever voltage the IAC required, I think a small transistor board would take care of that.

While I've got your attention. Anybody think there is enough room inside the microsquirt case to fit those tiny boards?

If not I'll just piggyback it on top of the housing. A picture of the case/housing opened up would be great.

I stumbled upon it when I found this:

Working 3D printed stepper motor

(I have no idea how I found it)