Unit is a MS1 running MSnS code (will be fuel only at first, though), with a 36-1 trigger wheel, and direct coil control of my HEI coil (EDIS 8 later). Engine is a 500hp 11.5:1 4.125x3.385 BxS Olds 350 with ported factory iron heads and no frills. Cam is a Lunati 418A1LUN solid flat tappet, and carburetor has been a ProSystems custom 820CFM Holley 4150. I'm using a dual plane manifold on this, as this engine did NOT like a single plane on the dyno. I'm doing most of the modifications myself. As this is 40 year old wiring, I decided to rewire the whole car; in the past I've upgraded component sections, but never pulled it all out and started over. What a mess. I'm about 90% done with the main system (still have to finish the engine harness and some gauges and such), and I'll test it before wrapping everything up and calling it done. Then on to the EFI, which you can see is already tested and ready to rock on the firewall.

Here's some pictures of the intake progress. First pic is the jig I built to grind step drills. It's really simple with the x-y table and depth stop. I have to manually make the back cuts, but I've had great success both with the 14mm stepped bit I made for the rails, as well as the 3/8" non-cutting pilot to 3/4" bit I used for the bung holes (lulz). Second picture is the intake on my bench with the injector hole locating jig in place after cutting the larger holes and test fitting the bungs for binding. I simply used angle iron and 3/8" ID tubing (using the rails as templates) and then positioned everything and drilled the 3/8" pilot holes. So far so good.

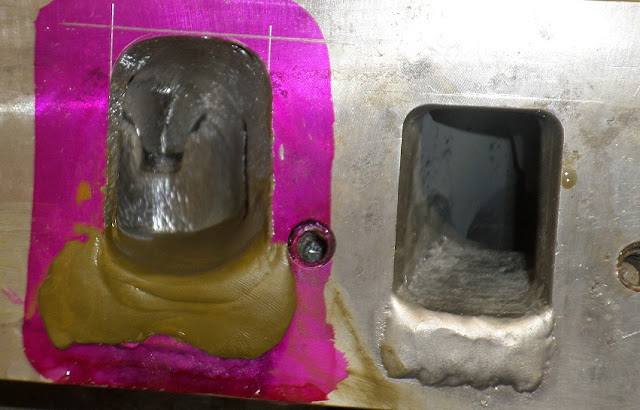

Here's the highly technical high-dollar setup I had fabricated to hold the bungs in place while I epoxied them. I had to start over on one side when I accidentally got some epoxy on an injector body (uuugh, I need junk units for this stuff!) but everything turned out great. I had to use the kitchen counter because it's the only perfectly level surface I could find in the house or garage, and I used a level to make sure the bungs were even front-to-back and bank-to-bank. The high-speed-low-drag tactical adhesive strip is holding the injectors vertical. ;)

Lastly, here's the product so far. I still need to make hold-down brackets (I'm playing with some design ideas, but I'm thinking I'll hold it down with straps coming up from the manifold-to-head bolts), but I've got the harnesses done. I wired it up so with a simple 4 to 1 weatherpack adapter I can switch from bank-to-bank at first to sequential later on. I'm going to use a dedicated weatherpack bulkhead for the EFI side of things, so I will literally be able to pull some connectors apart and throw a carb on it later on if I so desire.

To be continued...