VVT ideas and testers

Moderators: jsmcortina, muythaibxr

-

hoveringuy

- Experienced MS/Extra'er

- Posts: 172

- Joined: Fri Aug 29, 2008 8:52 am

Re: VVT ideas and testers

I have my intake cam running well on Alpha 14. If you look closely at the datalog you can see that the BMW VANOS has a bit of a stiction issue; it does not respond as linearly as I would like.

My recommendation at this point is that VVT either needs the ability to be disabled below a threshold CLT level, or the advance/retard needs to be scaled-down as a function of warmup enrichment. The advance profile that works well on a warm motor makes it misbehave at colder temps.

My recommendation at this point is that VVT either needs the ability to be disabled below a threshold CLT level, or the advance/retard needs to be scaled-down as a function of warmup enrichment. The advance profile that works well on a warm motor makes it misbehave at colder temps.

-

MidShipCivic

- MS/Extra Newbie

- Posts: 22

- Joined: Mon Jun 18, 2007 1:58 pm

Re: VVT ideas and testers

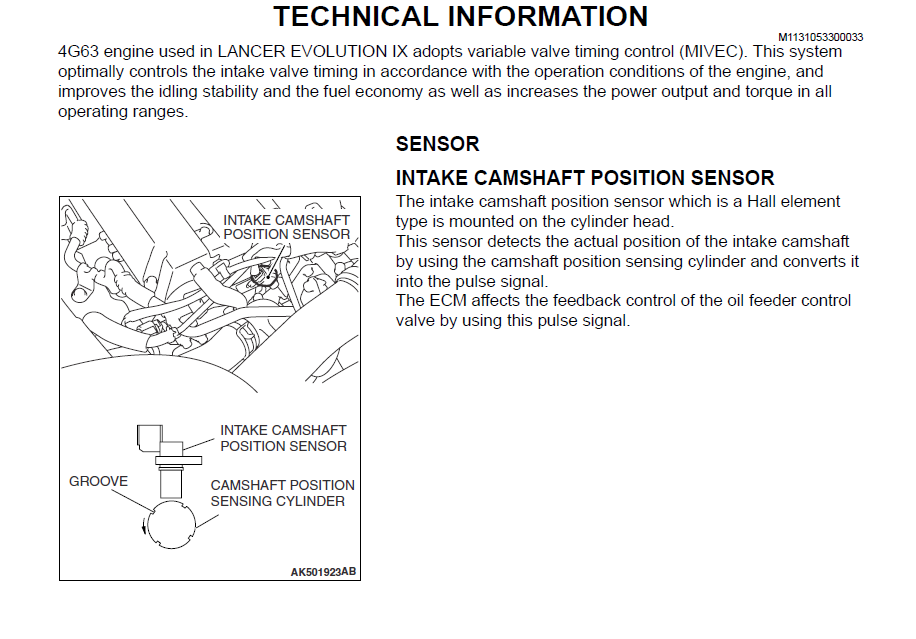

If OEM cam phasing systems use a position wheel with the number of teeth corresponding to the number of cylinders to tell which cylinder it's on how can cam 1 use MAIN cam input which is single tooth?

Can I have it to where I use a 4 tooth wheel on the primary camshaft?

Can I have it to where I use a 4 tooth wheel on the primary camshaft?

Eagle Talon TSI AWD (4g63)

-

hassmaschine

- Super MS/Extra'er

- Posts: 1331

- Joined: Mon May 21, 2007 8:36 am

Re: VVT ideas and testers

that's not how cam sensors work. the crank sensor tells the computer what cylinder is #1, the cam sensor tells the computer which cycle it's on (intake/exhaust). with a higher toothed cam wheel I'd imagine there's more precision in knowing the exact cam angles in a VVT system, but it's not strictly neccesary to have anymore than 1 tooth.MidShipCivic wrote:If OEM cam phasing systems use a position wheel with the number of teeth corresponding to the number of cylinders to tell which cylinder it's on how can cam 1 use MAIN cam input which is single tooth?

Can I have it to where I use a 4 tooth wheel on the primary camshaft?

-

MidShipCivic

- MS/Extra Newbie

- Posts: 22

- Joined: Mon Jun 18, 2007 1:58 pm

Re: VVT ideas and testers

hassmaschine wrote:that's not how cam sensors work. the crank sensor tells the computer what cylinder is #1, the cam sensor tells the computer which cycle it's on (intake/exhaust). with a higher toothed cam wheel I'd imagine there's more precision in knowing the exact cam angles in a VVT system, but it's not strictly neccesary to have anymore than 1 tooth.MidShipCivic wrote:If OEM cam phasing systems use a position wheel with the number of teeth corresponding to the number of cylinders to tell which cylinder it's on how can cam 1 use MAIN cam input which is single tooth?

Can I have it to where I use a 4 tooth wheel on the primary camshaft?

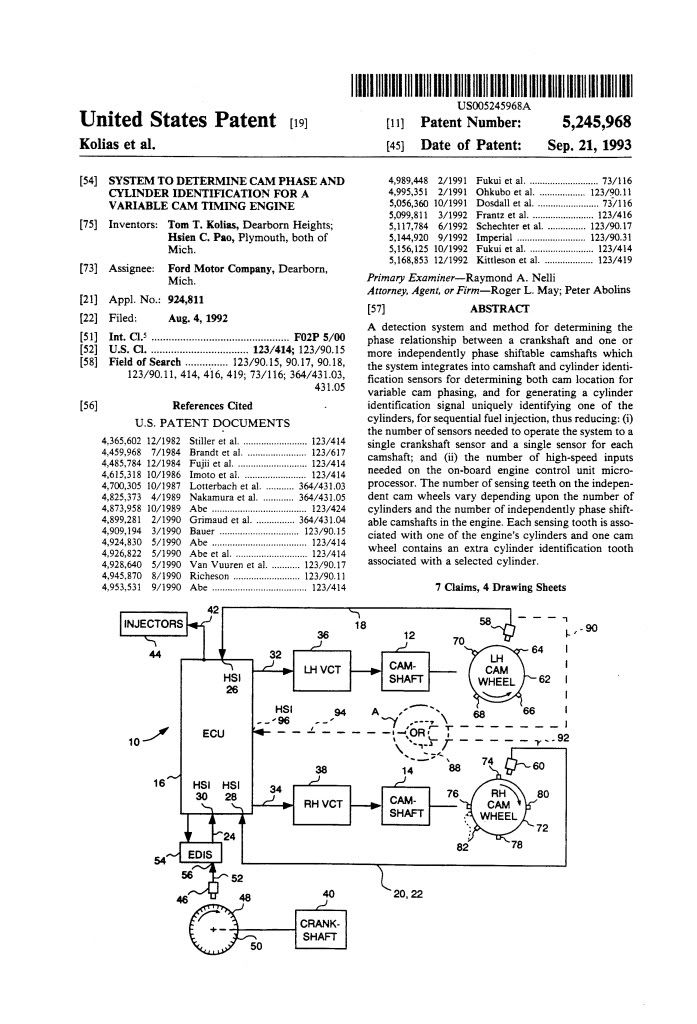

This is what I read in the patent that some systems also use this for cylinder position, however I do not know how Megasquirt uses them as there is little literature about it.

But the paper does let this be known 'This is typically is accomplished by configuring a system, and by adding a sensor to generate a cylinder identification signal (i.e. engine rotational position).'' ( the figure below is a v8 and one extra tooth on the RH cam wheel tells this)

What it also stated.

''In an additional alternative embodiment, the number of teeth for sensing the camshaft location and position double on each cam wheel to increase the sampling rate of the camshaft position.''

And on my engine (4 cylinder) seem to be under the same principal.

Eagle Talon TSI AWD (4g63)

-

jsmcortina

- Site Admin

- Posts: 39615

- Joined: Mon May 03, 2004 1:34 am

- Location: Birmingham, UK

- Contact:

Re: VVT ideas and testers

I don't see what relevance the extract from the Ford patent is. The Zetec VCT system is already supported.

What crank wheel arrangement does your engine use? I assume the engine is running wasted spark from the cam pattern.

James

What crank wheel arrangement does your engine use? I assume the engine is running wasted spark from the cam pattern.

James

I can repair or upgrade Megasquirts in UK. http://www.jamesmurrayengineering.co.uk

My Success story: http://www.msextra.com/forums/viewtopic ... 04&t=34277

MSEXTRA documentation at: http://www.msextra.com/doc/index.html

New users, please read the "Forum Help Page".

My Success story: http://www.msextra.com/forums/viewtopic ... 04&t=34277

MSEXTRA documentation at: http://www.msextra.com/doc/index.html

New users, please read the "Forum Help Page".

-

porelmundo

- Helpful MS/Extra'er

- Posts: 43

- Joined: Tue Dec 09, 2008 12:34 pm

Re: VVT ideas and testers

same problem here, a CLT threshold will patch the misbehave unil engine get to temperature.hoveringuy wrote:My recommendation at this point is that VVT either needs the ability to be disabled below a threshold CLT level, or the advance/retard needs to be scaled-down as a function of warmup enrichment. The advance profile that works well on a warm motor makes it misbehave at colder temps.

-

MidShipCivic

- MS/Extra Newbie

- Posts: 22

- Joined: Mon Jun 18, 2007 1:58 pm

Re: VVT ideas and testers

The relevance is how some camshaft sensor give cylinder position identification, I wanted to see if I could use a higher resolution wheel for VVT on the primary camshaft.jsmcortina wrote:I don't see what relevance the extract from the Ford patent is. The Zetec VCT system is already supported.

I seem to be confusing you guys. Is default for (VVT1)the single tooth wheel while remaining camshaft (using VVT) can use their oem multi tooth / groove trigger wheel patterns on MS3? I was trying to learn megasquirt configuration can that be changed?

The engine is a Mitsubishi 4g63 not Ford ZETEC.What crank wheel arrangement does your engine use? I assume the engine is running wasted spark from the cam pattern.

James

The OEM TDC sensor is a shutter wheel with two openings that bolts on the exhaust camshaft while VVT uses the 4 grooved sensor as pictured in the service manual in the earlier post.

You asked me the setup in previous post it's a 60-3 Bosch crank trigger wheel ( I changed it to this).

The engine was wastedspark from factory.

Eagle Talon TSI AWD (4g63)

Re: VVT ideas and testers

Time for a quick update on the long term use of CL VVT with a Volkswagen 1.8T VVT chain tensioner. Premature wear of the tensioner seems to be an issue but one that can _probably_ be solved. Basically controlling the valve with PWM based Closed loop intake cam timing beats the crap out of a plastic travel limiter in the plunger. Pieces of the limiter then clog the oil ports on the plunger and oil starvation and galling of the plunger is the end result. Not wonderfull but as I said, some very smart people are looking into the issue. A simple materials change might do the trick but we are also looking at making the valve bidirectional instead of advance only.

Linfert Performance/321 Motorsports

SCCA 2019 SM National Champion Crew Chief

SCCA 2023 FP National Champion Tuner/electrical engineer

100s of MS systems built installed and tuned

Support the developers!

SCCA 2019 SM National Champion Crew Chief

SCCA 2023 FP National Champion Tuner/electrical engineer

100s of MS systems built installed and tuned

Support the developers!

-

jsmcortina

- Site Admin

- Posts: 39615

- Joined: Mon May 03, 2004 1:34 am

- Location: Birmingham, UK

- Contact:

Re: VVT ideas and testers

Posting that is irrelevant because we already support it. You appear to be trying to tell us something that we already know and already do.MidShipCivic wrote:The relevance is how some camshaft sensor give cylinder position identification, I wanted to see if I could use a higher resolution wheel for VVT on the primary camshaft.jsmcortina wrote:I don't see what relevance the extract from the Ford patent is. The Zetec VCT system is already supported.

James

I can repair or upgrade Megasquirts in UK. http://www.jamesmurrayengineering.co.uk

My Success story: http://www.msextra.com/forums/viewtopic ... 04&t=34277

MSEXTRA documentation at: http://www.msextra.com/doc/index.html

New users, please read the "Forum Help Page".

My Success story: http://www.msextra.com/forums/viewtopic ... 04&t=34277

MSEXTRA documentation at: http://www.msextra.com/doc/index.html

New users, please read the "Forum Help Page".

-

MidShipCivic

- MS/Extra Newbie

- Posts: 22

- Joined: Mon Jun 18, 2007 1:58 pm

Re: VVT ideas and testers

That was a general statement I'm sure everyone can read here out of politeness since I don't assume anyone is ignorant here.jsmcortina wrote:Posting that is irrelevant because we already support it. You appear to be trying to tell us something that we already know and already do.MidShipCivic wrote:The relevance is how some camshaft sensor give cylinder position identification, I wanted to see if I could use a higher resolution wheel for VVT on the primary camshaft.jsmcortina wrote:I don't see what relevance the extract from the Ford patent is. The Zetec VCT system is already supported.

James

I've pmed you in the past and you haven't responded to any of my PM's. I'm not one to insult anyone, but if it was so irrelevant why address that instead of my curiosity of wheel resolution?

There is not much literature on what I can and can't do since I'm retrofitting an active camgear to my engine I'm simply trying to see whats possible.

Eagle Talon TSI AWD (4g63)

-

jsmcortina

- Site Admin

- Posts: 39615

- Joined: Mon May 03, 2004 1:34 am

- Location: Birmingham, UK

- Contact:

Re: VVT ideas and testers

Maybe it would help if you started a new topic asking just those questions clearly and specifying exactly what your engine is etc.MidShipCivic wrote:There is not much literature on what I can and can't do since I'm retrofitting an active camgear to my engine I'm simply trying to see whats possible.

All support questions should be posted to the forum. I usually just delete any PM support requests.

James

I can repair or upgrade Megasquirts in UK. http://www.jamesmurrayengineering.co.uk

My Success story: http://www.msextra.com/forums/viewtopic ... 04&t=34277

MSEXTRA documentation at: http://www.msextra.com/doc/index.html

New users, please read the "Forum Help Page".

My Success story: http://www.msextra.com/forums/viewtopic ... 04&t=34277

MSEXTRA documentation at: http://www.msextra.com/doc/index.html

New users, please read the "Forum Help Page".

Re: VVT ideas and testers

Ok so now I will possibly be asking some stupid questions as I am not a techie more nuts and bolts!

I am about to install a ST170 engine in my Westfield I have MS3 with expansion board, I am struggling to find data/information on how to set up, I have found a fuel map and a little bit on the cam advance

Map from DTA who do the S60 ecu which will do PWM for fully variable/programmable cam timing. All full throttle, they use 50 at 2500rpm, 60 at 4500 and 40 at 5500 and above.

My request for info is where do I find out the information to fill out the VVT settings table

Told you it would be stupid, I appreciate I have a lot to learn but I am sure there are others out there wanting the same info, well I know thats the case as I know another person doing exactly the same mod as me.

In your response if you can be more simplistic in your response I would appreciate atleast then you should get more feed back from a VVT and MS3 novice, happy to share and continue to test

Chris

sorry if the posting isin the wrong area

I am about to install a ST170 engine in my Westfield I have MS3 with expansion board, I am struggling to find data/information on how to set up, I have found a fuel map and a little bit on the cam advance

Map from DTA who do the S60 ecu which will do PWM for fully variable/programmable cam timing. All full throttle, they use 50 at 2500rpm, 60 at 4500 and 40 at 5500 and above.

My request for info is where do I find out the information to fill out the VVT settings table

Told you it would be stupid, I appreciate I have a lot to learn but I am sure there are others out there wanting the same info, well I know thats the case as I know another person doing exactly the same mod as me.

In your response if you can be more simplistic in your response I would appreciate atleast then you should get more feed back from a VVT and MS3 novice, happy to share and continue to test

Chris

sorry if the posting isin the wrong area

Re: VVT ideas and testers

I'm planning for BMW S54 VANOS actuation.

The engine uses two solenoids for each camshaft. On both cams, if you open the "inlet" solenoid it adds advance, if you open the "outlet" solenoid it adds retard, and keeping both closed holds the cam position.

Is there any reason that we couldn't do the following:

- set PID parameters with Intake - More duty means - Advance

- set PID parameters with Exhaust - More duty means - Retard

- set CAM1 as Intake (will control S54 intake cam inlet solenoid)

- set CAM2 as Exhaust (will control S54 intake cam outlet solenoid)

- set CAM3 as Intake (will control S54 exhaust cam inlet solenoid)

- set CAM4 as Exhaust (will control S54 exhaust cam outlet solenoid)

- set CAM1 and CAM2 maps identically, as both control the intake cam position

- set CAM3 and CAM4 maps identically, as both control the exhaust cam position

Does this make sense to anybody except me? Configuring each of the four channels as a "push" channel?

The engine uses two solenoids for each camshaft. On both cams, if you open the "inlet" solenoid it adds advance, if you open the "outlet" solenoid it adds retard, and keeping both closed holds the cam position.

Is there any reason that we couldn't do the following:

- set PID parameters with Intake - More duty means - Advance

- set PID parameters with Exhaust - More duty means - Retard

- set CAM1 as Intake (will control S54 intake cam inlet solenoid)

- set CAM2 as Exhaust (will control S54 intake cam outlet solenoid)

- set CAM3 as Intake (will control S54 exhaust cam inlet solenoid)

- set CAM4 as Exhaust (will control S54 exhaust cam outlet solenoid)

- set CAM1 and CAM2 maps identically, as both control the intake cam position

- set CAM3 and CAM4 maps identically, as both control the exhaust cam position

Does this make sense to anybody except me? Configuring each of the four channels as a "push" channel?

-

jsmcortina

- Site Admin

- Posts: 39615

- Joined: Mon May 03, 2004 1:34 am

- Location: Birmingham, UK

- Contact:

Re: VVT ideas and testers

I'm looking for one tester who presently uses more than one VVT camshaft with alpha18. I've made some code changes to support 2+ cams and want to verify that I didn't break the existing support.

James

James

I can repair or upgrade Megasquirts in UK. http://www.jamesmurrayengineering.co.uk

My Success story: http://www.msextra.com/forums/viewtopic ... 04&t=34277

MSEXTRA documentation at: http://www.msextra.com/doc/index.html

New users, please read the "Forum Help Page".

My Success story: http://www.msextra.com/forums/viewtopic ... 04&t=34277

MSEXTRA documentation at: http://www.msextra.com/doc/index.html

New users, please read the "Forum Help Page".

-

hoveringuy

- Experienced MS/Extra'er

- Posts: 172

- Joined: Fri Aug 29, 2008 8:52 am

Re: VVT ideas and testers

Wouldn't work because the intake cam Exhaust channel is looking at the position of the actual exhaust cam. It would be simpler to implement an H-bridge circuit. Also, S54 solenoid polarity is backwards unless you remove the diodes.nucci wrote:I'm planning for BMW S54 VANOS actuation.

The engine uses two solenoids for each camshaft. On both cams, if you open the "inlet" solenoid it adds advance, if you open the "outlet" solenoid it adds retard, and keeping both closed holds the cam position.

Is there any reason that we couldn't do the following:

- set PID parameters with Intake - More duty means - Advance

- set PID parameters with Exhaust - More duty means - Retard

- set CAM1 as Intake (will control S54 intake cam inlet solenoid)

- set CAM2 as Exhaust (will control S54 intake cam outlet solenoid)

- set CAM3 as Intake (will control S54 exhaust cam inlet solenoid)

- set CAM4 as Exhaust (will control S54 exhaust cam outlet solenoid)

- set CAM1 and CAM2 maps identically, as both control the intake cam position

- set CAM3 and CAM4 maps identically, as both control the exhaust cam position

Does this make sense to anybody except me? Configuring each of the four channels as a "push" channel?

I don't believe the S54 cam profile is currently supported.

I was using two cams with Alpha 17, but Alpha 18 did something to my exhaust cam that I had to deactivate it.jsmcortina wrote:I'm looking for one tester who presently uses more than one VVT camshaft with alpha18. I've made some code changes to support 2+ cams and want to verify that I didn't break the existing support.

James

The exhaust cam gets retarded up to 40 degrees from the default position. In Alpha 17 I had to have all 40's in the table to keep it advanced at the default setting. Values towards '0' retarded it. It appears that in Alpha 18 the same default 40 values were now retarding the cam and I couldn't get it to stay running until I deactivated the exhaust cam, haven't trouble-shot yet.

-

jsmcortina

- Site Admin

- Posts: 39615

- Joined: Mon May 03, 2004 1:34 am

- Location: Birmingham, UK

- Contact:

Re: VVT ideas and testers

I've re-checked the ChangeLog and still don't see any changes relating to VVT between alpha17 and 18. So I don't see how behaviour could be different at this point.hoveringuy wrote:I was using two cams with Alpha 17, but Alpha 18 did something to my exhaust cam that I had to deactivate it.

The exhaust cam gets retarded up to 40 degrees from the default position. In Alpha 17 I had to have all 40's in the table to keep it advanced at the default setting. Values towards '0' retarded it. It appears that in Alpha 18 the same default 40 values were now retarding the cam and I couldn't get it to stay running until I deactivated the exhaust cam, haven't trouble-shot yet.

James

I can repair or upgrade Megasquirts in UK. http://www.jamesmurrayengineering.co.uk

My Success story: http://www.msextra.com/forums/viewtopic ... 04&t=34277

MSEXTRA documentation at: http://www.msextra.com/doc/index.html

New users, please read the "Forum Help Page".

My Success story: http://www.msextra.com/forums/viewtopic ... 04&t=34277

MSEXTRA documentation at: http://www.msextra.com/doc/index.html

New users, please read the "Forum Help Page".

-

WORKS

- MS/Extra Newbie

- Posts: 16

- Joined: Fri Feb 17, 2012 10:58 am

- Location: Sears Point Raceway, CA

- Contact:

Re: VVT ideas and testers

We are currently implementing intake VVT in our 2009 Mitsubishi Ralliart Touring Car with the 4B11.

We are using 1.1 Alpha 18 with a 36-1 crank wheel and a 50/50 half moon polled cam wheel.

We are able to move the cam in TEST mode but there are two issues:

1. The VVT 1 angle gauge on the gauge cluster is not displaying the angle.

2. Populating the "VVT intake table" seems to have no effect. However Test mode and On/Off mode works.

Matt recommended changing the 'Poll Level' to 'Rising Edge' or 'Falling Edge' which does not appear to do anything.

Does anybody have any ideas or recommendations?

We are using 1.1 Alpha 18 with a 36-1 crank wheel and a 50/50 half moon polled cam wheel.

We are able to move the cam in TEST mode but there are two issues:

1. The VVT 1 angle gauge on the gauge cluster is not displaying the angle.

2. Populating the "VVT intake table" seems to have no effect. However Test mode and On/Off mode works.

Matt recommended changing the 'Poll Level' to 'Rising Edge' or 'Falling Edge' which does not appear to do anything.

Does anybody have any ideas or recommendations?

-

jsmcortina

- Site Admin

- Posts: 39615

- Joined: Mon May 03, 2004 1:34 am

- Location: Birmingham, UK

- Contact:

Re: VVT ideas and testers

Does your cam "tooth" move when the cam VVT position changes? If not that you can't use it to sense cam position and the angle gauge won't move.

James

James

I can repair or upgrade Megasquirts in UK. http://www.jamesmurrayengineering.co.uk

My Success story: http://www.msextra.com/forums/viewtopic ... 04&t=34277

MSEXTRA documentation at: http://www.msextra.com/doc/index.html

New users, please read the "Forum Help Page".

My Success story: http://www.msextra.com/forums/viewtopic ... 04&t=34277

MSEXTRA documentation at: http://www.msextra.com/doc/index.html

New users, please read the "Forum Help Page".

-

WORKS

- MS/Extra Newbie

- Posts: 16

- Joined: Fri Feb 17, 2012 10:58 am

- Location: Sears Point Raceway, CA

- Contact:

Re: VVT ideas and testers

Yes, the cam tooth is machined on the end of the one piece camshaft.

WORKS

Infineon Raceway L-1B

Dynapack hub dyno and racetrack

POWER | PRECISION | PASSION

415-226-2500

http://www.worksmotorsports.com

Infineon Raceway L-1B

Dynapack hub dyno and racetrack

POWER | PRECISION | PASSION

415-226-2500

http://www.worksmotorsports.com

-

hoveringuy

- Experienced MS/Extra'er

- Posts: 172

- Joined: Fri Aug 29, 2008 8:52 am

Re: VVT ideas and testers

I went back to Alpha 17 and everything worked fine.jsmcortina wrote: I've re-checked the ChangeLog and still don't see any changes relating to VVT between alpha17 and 18. So I don't see how behaviour could be different at this point.

James

Re-installed 18 and had issues again.

Found that VVT2 worked fine in test mode, but that the VVT2 gauge wasn't showing changes in cam position, even though I could hear the engine responding. I'm using Datalog PT6 as my input channel. Any changes with that?

One other peculiarity, both in 17 and 18, is that the duty seems to be backwards for exhaust. For my intake cam duty of 0% means the solenoid is getting no power. On the exhaust cam a reported duty of 100% means the solenoid is getting no power (verified on my oscilloscope) 0% gives me full retard on the exhaust cam.