apocalight wrote:Can you elaborate on how a 12 or 6 position would affect it more (or perhaps less). Push come to shove, I can slot the bolt holes for the block and move the entire thing up a few mm. Just trying to avoid that at the moment.

First, let me clear! I am

not suggesting that you need to change your sensor location. Quite the opposite! In fact, I would

not move it if it were mine!

It is my belief/understanding that, due to crankshaft flex and bearing clearances, the crankshaft

may move a

very small distance,

under heavy load. This movement would generally be more in the vertical axis rather than horizontal (unless of course, you have one of those funny looking horizontally opposed motors!

). Furthermore, I seriously doubt that such a small movement would have

any effect on sensor clearance.

From my earlier post:

kjones6039 wrote:If the sensor were mounted at the 12 or 6 o'clock position, it might be another matter altogether.

FWIW, I think it's worth a try (in it's present location).

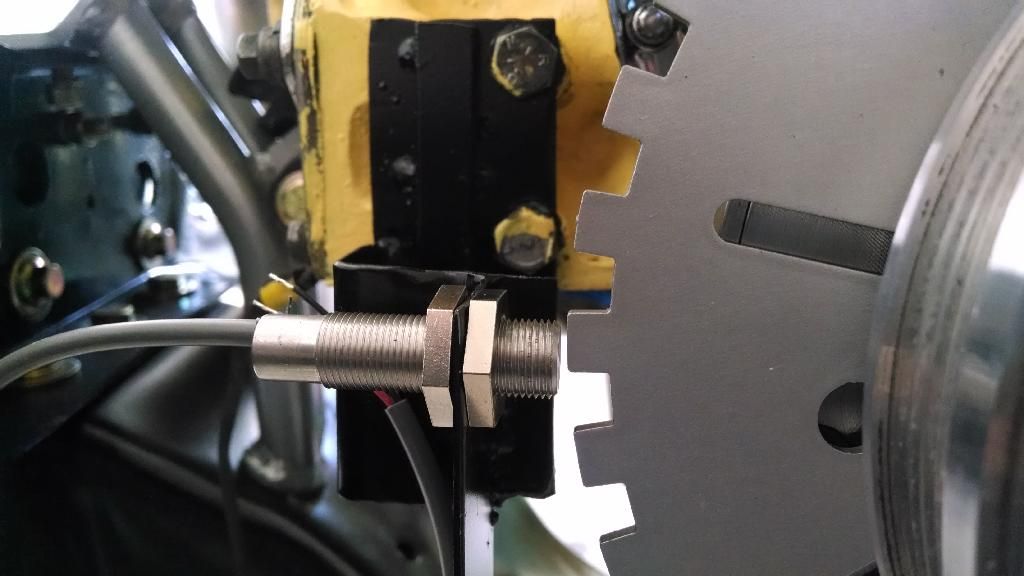

In my case, my sensor is located ~15* below the crankshaft center line (9 o'clock). and has

never suffered any ill effects from being installed in that location.

My suggestion........ quit worrying about it!

Ken

1979 Corvette - 383 CID SBC w/ Holley Pro-Jection 900 CFM TBI, 4-85 lb lo-z injectors & Walbro 255 pump

MS2 v3 w/extra 3.4.2 Release

36-1, Delphi LS2/7 coils in wasted spark, driven by v2.0 logic board from JBPerformance

Spartan Lambda Sensor from 14point7

TinyIOX from JBPerformance