5.2L Magnum MS3/MS3x

Moderators: jsmcortina, muythaibxr

5.2L Magnum MS3/MS3x

I have been working on installing a MS3/MS3X V3.57 on my 5.2l Magnum that is in my 1990 Jeep Wrangler. I will be replacing the stock computer and running sequential fuel and spark with coils from a 5.3l vortec. Currently on the composite logger I see lines for cam, sync loss consistently and occasionally I will see one blue line for the crank. The crank sensor is wired with the 5v (I've tried 12v as well) and the white and black wire in the shield. I've tried different tooth angle from what other people online have said. I've looked over the internal jumpers per the manual and twisted the pots but I am lost for what to do next to get crank sensor signal.

My ignition settings are as follow:

Spark Mode: Toothed Wheel

Ignition Input Capture: Rising Edge

Spark Output: Going High

Number of Coils: Coil on Plug

Spark Hardware: MS3x

Cam Input: MS3x Cam in

Trigger Wheel Arrangement: Dual Wheel

Trigger Wheel Teeth: 8

Missing Teeth: 0

Tooth #1 Angle: 0

Main Wheel Speed: Crank Wheel

Second Trigger: Falling Edge

Every Rotation of: Cam

My ignition settings are as follow:

Spark Mode: Toothed Wheel

Ignition Input Capture: Rising Edge

Spark Output: Going High

Number of Coils: Coil on Plug

Spark Hardware: MS3x

Cam Input: MS3x Cam in

Trigger Wheel Arrangement: Dual Wheel

Trigger Wheel Teeth: 8

Missing Teeth: 0

Tooth #1 Angle: 0

Main Wheel Speed: Crank Wheel

Second Trigger: Falling Edge

Every Rotation of: Cam

Re: 5.2L Magnum MS3/MS3x

If I pull the crank sensor from the engine and brush it against metal I can see it show up on the composite logger. When I put it back in the engine I might get one blue line for 20 sec of cranking. Not sure if it matters but the cam has a solid green line at the top and lines going down from there evenly spaced. The crank wheel is 8 even notches and the cam sensor is hall with a half moon.

Re: 5.2L Magnum MS3/MS3x

Anybody please? I can't figure out why during cranking the sensor is showing only .7v but if I turn the engine by hand I can see it switch from 0v to 5v?

I have a week left to get this engine running before I need to leave for 29 palms.

I have a week left to get this engine running before I need to leave for 29 palms.

-

billr

- Super MS/Extra'er

- Posts: 6828

- Joined: Sun May 15, 2011 11:41 am

- Location: Walnut Creek, Calif. USA

Re: 5.2L Magnum MS3/MS3x

Post the name and P/N of the CKP sensor and a picture of the wheel and sensor. What air gap do you have?

Re: 5.2L Magnum MS3/MS3x

Duralast SU395 for a 96 Ram 1500 5.2l Manual Transmission. The sensor with the metal showing is the sensor that was on the engine when it was running with the stock computer, I don't know brand or part number for it. The one with the 2 on the bottom is the new duralast from autozone. This is the best picture I can get of the wheel unless I drop the transmission. I'm assuming air gap is the distance between the sensor and the crank wheel?

Re: 5.2L Magnum MS3/MS3x

Another question, can multimeter even see the signal of the sensor switching at those speeds in a 0-5v signal? However even in tooth logger I get nothing.

-

billr

- Super MS/Extra'er

- Posts: 6828

- Joined: Sun May 15, 2011 11:41 am

- Location: Walnut Creek, Calif. USA

Re: 5.2L Magnum MS3/MS3x

Yes, a voltmeter can easily see the output from that Hall sensor, no matter how slow you move it. In fact, the output should "toggle" on/off and remain steady, depending on whether there is ferrous metal in front of the sensor; you can test it away from the trigger wheel, just using anything made of steel to place/remove from the sensor face. Do you have a pull-up resistor installed in the MS CKP circuit? Have you adjusted the pots per the manual, using a meter to measure the settings?

It looks like the air-gap is "fixed" by the OEM mounting, so that should not be a problem. Do you know, for sure, if the OEM use of that sensor powered it with 5V or 12V? Or, maybe something else (like 8V)? Chrysler was known to do odd things; witness that your sensor, for a manual trans, is different than the same engine with an auto trans...

It looks like the air-gap is "fixed" by the OEM mounting, so that should not be a problem. Do you know, for sure, if the OEM use of that sensor powered it with 5V or 12V? Or, maybe something else (like 8V)? Chrysler was known to do odd things; witness that your sensor, for a manual trans, is different than the same engine with an auto trans...

Re: 5.2L Magnum MS3/MS3x

I have tested both sensors away from the trigger wheel and was able to get it to show on the composite logger by tapping the sensor against metal on the engine. As far as voltage the FSM pinout says 5v supply for the power but I have also tried 12v.

I do not have a pull up wired in, if I read the instructions right it said it has an internal pull up of it has the 5v ungrounded 0v grounded. I've also done the pots per the manual twice.

I do not have a pull up wired in, if I read the instructions right it said it has an internal pull up of it has the 5v ungrounded 0v grounded. I've also done the pots per the manual twice.

-

billr

- Super MS/Extra'er

- Posts: 6828

- Joined: Sun May 15, 2011 11:41 am

- Location: Walnut Creek, Calif. USA

Re: 5.2L Magnum MS3/MS3x

Try using the meter to test output, not the composite logger. You should *probably* see a very definite change from low (0V) to high (5V) as the sensor sees a piece of steel/iron; and the readings should hold steady as long as the target is kept steady relative to the sensor face.

I say "probably" because some Hall gear-tooth sensors have more than one Hall element (I'm thinking of the Allegro chips) and operation is determined by sensing the difference in the magnetic field that each element sees; direction of the target travel, as it is moved into position near the sensor face, and target size matter.

I would try adding a pull-up resistor, even if just temporarily out at the sensor connector. If you use about 4700 ohms it shouldn't bother anything , if there already is an internal pull-up.

I say "probably" because some Hall gear-tooth sensors have more than one Hall element (I'm thinking of the Allegro chips) and operation is determined by sensing the difference in the magnetic field that each element sees; direction of the target travel, as it is moved into position near the sensor face, and target size matter.

I would try adding a pull-up resistor, even if just temporarily out at the sensor connector. If you use about 4700 ohms it shouldn't bother anything , if there already is an internal pull-up.

Re: 5.2L Magnum MS3/MS3x

I'm not sure if there is any places near me that sell resistors but I'll definitely give it a shot. Now for the pots, how do they affect how the MS reads the sensor? If improperly adjusted will cause the crank sensor to not show in the tooth or composite logger? I adjusted the pots per the manual but I could never hear a click going CCW, should I just set it so I get the 2.5v on the top of pin 54?

-

billr

- Super MS/Extra'er

- Posts: 6828

- Joined: Sun May 15, 2011 11:41 am

- Location: Walnut Creek, Calif. USA

Re: 5.2L Magnum MS3/MS3x

The "click" is often hard to hear or feel; so just turn the screw about 15 revolutions, you will then be at the end of travel, as those are 12-turn or 7-turn pots. No harm will be done by "going too far" since that is what the click is, a clutch in the pot releasing when the pot wiper is at the end of its travel. Yes, where the manual specifies looking for a voltage as result of adjusting the pot, go for that voltage reading.

An 8-tooth crank wheel with half-moon cam should show a continuous series of vertical blue lines and similar vertical green lines at 1/16 the frequency of the crank (blue) lines.

An 8-tooth crank wheel with half-moon cam should show a continuous series of vertical blue lines and similar vertical green lines at 1/16 the frequency of the crank (blue) lines.

Re: 5.2L Magnum MS3/MS3x

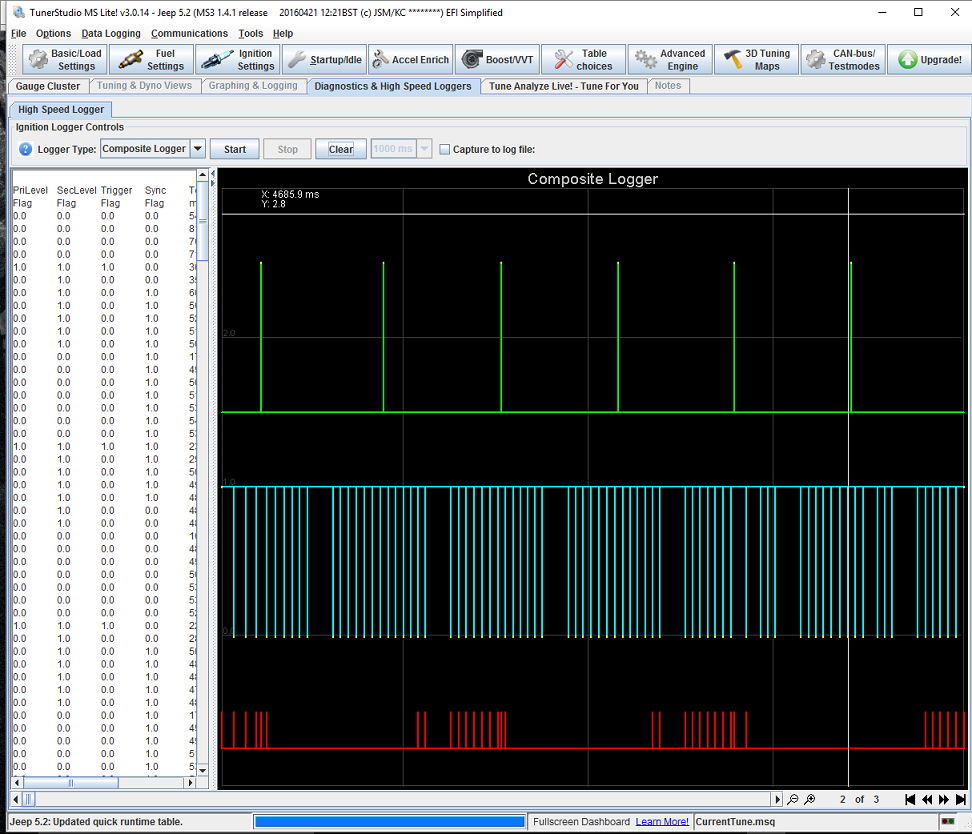

From that composite log, would you say I need to adjust my pots more? Does the #1 tooth angle affect the graph in the loggers or is that just for making sure you are zerod out on timing?

I want to say I really appreciate you helping me, I've been beating my head against a wall trying to figure this out.

I want to say I really appreciate you helping me, I've been beating my head against a wall trying to figure this out.

-

jsmcortina

- Site Admin

- Posts: 39617

- Joined: Mon May 03, 2004 1:34 am

- Location: Birmingham, UK

- Contact:

Re: 5.2L Magnum MS3/MS3x

Tooth #1 angle has no effect on the loggers. Looks like you are missing three crank teeth, I only count thirteen and there's a gap.

James

James

I can repair or upgrade Megasquirts in UK. http://www.jamesmurrayengineering.co.uk

My Success story: http://www.msextra.com/forums/viewtopic ... 04&t=34277

MSEXTRA documentation at: http://www.msextra.com/doc/index.html

New users, please read the "Forum Help Page".

My Success story: http://www.msextra.com/forums/viewtopic ... 04&t=34277

MSEXTRA documentation at: http://www.msextra.com/doc/index.html

New users, please read the "Forum Help Page".

Re: 5.2L Magnum MS3/MS3x

I adjusted the pots more and am getting 16 crank signals in 1 cam signal. I got everything else buttoned up and am trying to start it now. However the best I've been able to get is like a 5 second run before she dies regardless of throttle. I've tried changing timing, fuel, ase, wue, ignition capture etc. I also don't exactly understand the tooth angle, since I have the half moon where do I consider the tooth part? According to the manuals it's tdc rotate backwards until cam tooth is online with the sensor then forward until first crank tooth which I assume is the notches. Which gives me 30 degree however the engine won't even try starting. If I bump it up to around 360 it will catch but then die.

Running sequential fuel and spark.

Running sequential fuel and spark.

Re: 5.2L Magnum MS3/MS3x

Heres a composite log of a 5 second run

-

billr

- Super MS/Extra'er

- Posts: 6828

- Joined: Sun May 15, 2011 11:41 am

- Location: Walnut Creek, Calif. USA

Re: 5.2L Magnum MS3/MS3x

Post the MSQ and MSL files.

-

93supercoupe

- Master MS/Extra'er

- Posts: 581

- Joined: Sat May 10, 2014 4:57 am

- Location: New Haven, Ct, USA

Re: 5.2L Magnum MS3/MS3x

first tooth angle should be adjusted so that your timing light sees what you are commanding. Should be basically the first thing you should be doing.

Under ignition settings, put the spark in fixed mode and command something that you have an index for. Example- if you have a 0 mark on you lower cover, set the fixed angle to 0. If you have a 10degree mark on your cover, set it to 10.

Then adjust the first tooth angle until it lines up. You can do this at cranking speed.

Start there before worrying about why it doesnt run because first tooth angle is the most critical.

Under ignition settings, put the spark in fixed mode and command something that you have an index for. Example- if you have a 0 mark on you lower cover, set the fixed angle to 0. If you have a 10degree mark on your cover, set it to 10.

Then adjust the first tooth angle until it lines up. You can do this at cranking speed.

Start there before worrying about why it doesnt run because first tooth angle is the most critical.

BootlegTuned

Re: 5.2L Magnum MS3/MS3x

That was one of the first things I did. I set cranking timing to 0 and fixed to 0. Then I got the timing mark to line up to my TDC mark on my cover which was 318 tooth angle. Then I tried to start it with timing turned on but it just gurgles. After I tried going 180/360 out of that but nothing.93supercoupe wrote:first tooth angle should be adjusted so that your timing light sees what you are commanding. Should be basically the first thing you should be doing.

Under ignition settings, put the spark in fixed mode and command something that you have an index for. Example- if you have a 0 mark on you lower cover, set the fixed angle to 0. If you have a 10degree mark on your cover, set it to 10.

Then adjust the first tooth angle until it lines up. You can do this at cranking speed.

Start there before worrying about why it doesnt run because first tooth angle is the most critical.

The attached msq I was messing with some of the tables so I might honestly need to start from scratch. There is a msl while cranking.

-

billr

- Super MS/Extra'er

- Posts: 6828

- Joined: Sun May 15, 2011 11:41 am

- Location: Walnut Creek, Calif. USA

Re: 5.2L Magnum MS3/MS3x

Wow, you are throwing a lot of fuel at it! I would sure like to see the MSQ. Disable fueling, let it "air out" for a while, and try firing it with starting-fluid (fueling still disabled). Let's see if this is *just* a fueling problem.