300zx crank trigger selection

Moderators: jsmcortina, muythaibxr

300zx crank trigger selection

Hi,

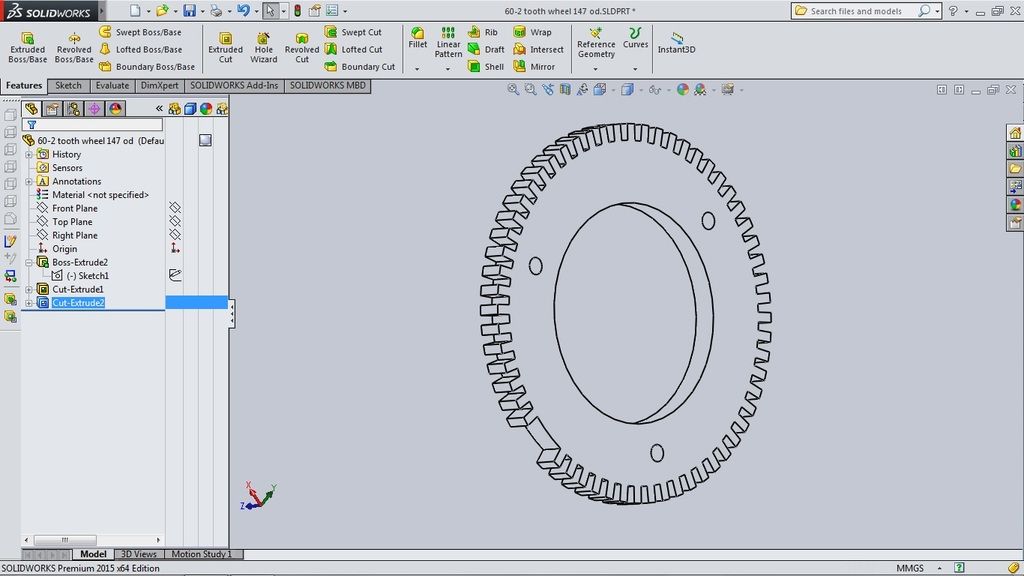

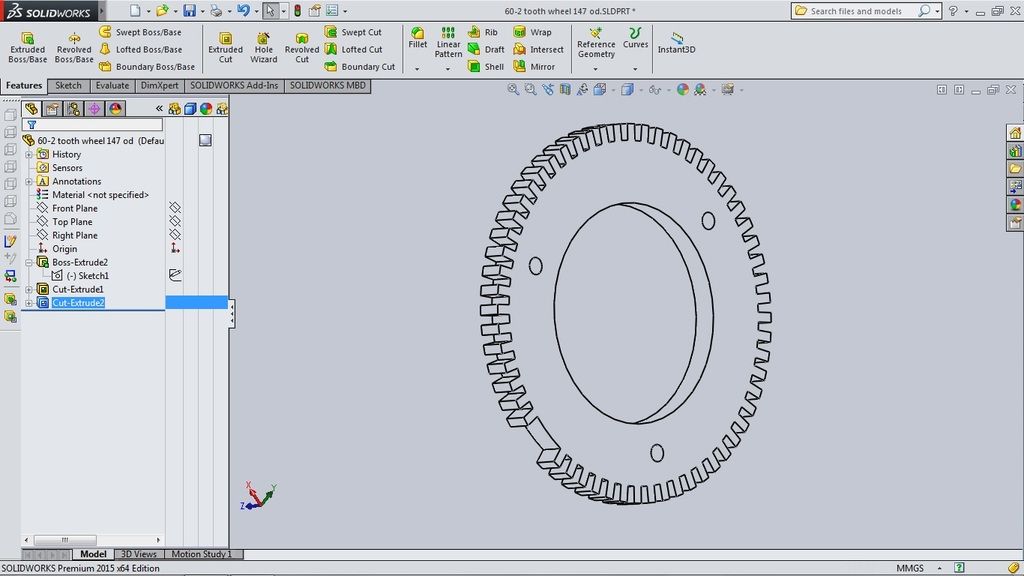

I have a ms3x v3.0 and want to use a crank trigger setup to avoid timing drift and blown motor. From reading the manual numerous times it seems easiest to set up a non missing tooth wheel and cam home. Using a 60-2 seems to be the best for timing accuracy and I like that but it also means im somewhat restricted in where I place the sensor to get correct phasing. Ive draft all my own gears on solidworks so its easy for me to change back and forth (just get them laser cut again).

so bottom line on a max effort engine (nitrous, turbo, e85)

12 tooth non missing with cam home

go to extra effort for 60-2 with cam home.

how much better is it.

thanks in advance

I have a ms3x v3.0 and want to use a crank trigger setup to avoid timing drift and blown motor. From reading the manual numerous times it seems easiest to set up a non missing tooth wheel and cam home. Using a 60-2 seems to be the best for timing accuracy and I like that but it also means im somewhat restricted in where I place the sensor to get correct phasing. Ive draft all my own gears on solidworks so its easy for me to change back and forth (just get them laser cut again).

so bottom line on a max effort engine (nitrous, turbo, e85)

12 tooth non missing with cam home

go to extra effort for 60-2 with cam home.

how much better is it.

thanks in advance

-

billr

- Super MS/Extra'er

- Posts: 6828

- Joined: Sun May 15, 2011 11:41 am

- Location: Walnut Creek, Calif. USA

Re: 300zx crank trigger selection

It is easiest to use a missing-tooth wheel, not the other way around! With missing-tooth you can get it up-and-running (and keep it running) even if the cam input is totally wrong/dead. With missing tooth (60-2, 36-1, or any other) there is no restriction on where you can put the sensor; especially if you can "clock" the crank wheel with the gap anywhere you want relative to TDC.

Re: 300zx crank trigger selection

Thanks for your reply I appreciate it. Ill put in some slots so I can "clock" the wheel.... hopefully the bolts dont come undone hahahaha

Re: 300zx crank trigger selection

sorry another question.

36-1 vs 60-2 (i have designs for both) Many searches suggest that you get sync loss on the 60-2 with high rpms. I will be using the DIY hall sensor (threaded) will it be able to cope with up to 9000rpm 60-2? I like the idea of timing accuracy but hate the thought of issues with sync loss

36-1 vs 60-2 (i have designs for both) Many searches suggest that you get sync loss on the 60-2 with high rpms. I will be using the DIY hall sensor (threaded) will it be able to cope with up to 9000rpm 60-2? I like the idea of timing accuracy but hate the thought of issues with sync loss

Re: 300zx crank trigger selection

A 60-2 tooth trigger wheel when combined with a VR sensor can have high speed sync issues but its super easy to deal with. If you are using a Max 9926 based conditioner ( Microsquirt and MS3 Pro based systems) a 10K shunt resistor across VR + and VR- fixes it. V3.0/V3.57 boards need a 10K resistor inline on VR+ . I have daily driven both styles for over 40,000 miles without issue.

No known issues that I am aware of using a Hall effect sensor and 60-2 except possibly frequency limitations on the sensor itself but that shouldn't be an issue with the Cherry sensor that DIY sells.

No known issues that I am aware of using a Hall effect sensor and 60-2 except possibly frequency limitations on the sensor itself but that shouldn't be an issue with the Cherry sensor that DIY sells.

Linfert Performance/321 Motorsports

SCCA 2019 SM National Champion Crew Chief

SCCA 2023 FP National Champion Tuner/electrical engineer

100s of MS systems built installed and tuned

Support the developers!

SCCA 2019 SM National Champion Crew Chief

SCCA 2023 FP National Champion Tuner/electrical engineer

100s of MS systems built installed and tuned

Support the developers!

-

billr

- Super MS/Extra'er

- Posts: 6828

- Joined: Sun May 15, 2011 11:41 am

- Location: Walnut Creek, Calif. USA

Re: 300zx crank trigger selection

When you "clock" the wheel, be sure the missing-tooth gap passes the sensor during the crank angle recommended in the manual for your type engine (V8, I4, V6...). This isn't critical when the engine is running, but can help get good sync when cranking and the crank rotational speed varies a lot at each compression stroke.

Re: 300zx crank trigger selection

Im waiting for the laser cutter to give me my first version. tooth spacing is 4mm. with a 4mm thick tooth 5mm deep (mild steel) and 7mm tooth height. hopefully that will get a good signal otherwise i have to go bigger diameter as the lasercutter needs the 4mm spacing therefore restricting my tooth thickness. could always go thicker with the steel i suppose. thoughts, suggestions?

-

billr

- Super MS/Extra'er

- Posts: 6828

- Joined: Sun May 15, 2011 11:41 am

- Location: Walnut Creek, Calif. USA

Re: 300zx crank trigger selection

Since you are cutting your own, consider "filling" the missing-tooth gaps, rather than removing the teeth. I have seen some better results doing that in some wheel/sensor experiments I've done. With a VR sensor this make a 60-2 a 60-3, or a 36-1 a 36-2; and the FW handles those fine. Take a peek at what Electromotive does with their 60-2 wheel. I always thought it was for balancing, but am now convinced it helps signal detection. That said, I have been running a simple 60-2 with missing tooth for years with no resistors and no problem, up to 6400 rpm. In tests, I have run 60-2 up towards 12K rpm, again with no resistors, but with the 60-3 "filled" I can push it up towards 17K. The problems I have seen aren't specifically at the higher rpm, but I couldn't set the pots for picking up both high and low rpm as well with 60-2 as I could with 60-3 "filled" (same for 36-1 vs 36-2 "filled). Again, only testing with VR.

Another consideration is the size of the sensor. The "pole" in the sensor, whether VR or Hall, has to be somewhat matched to the size of the target (wheel teeth). I would use a physical tooth size as suggested by the sensor vendor, even if it meant dropping back to 36-1. In my case I have a thin (1/8" thick) wheel with about .200" for teeth and .200" for gaps, about 1/8" deep. But, my VR sensor is only 3/8" OD, so the pole is about 1/8" diameter and well-matched to the size of the wheel teeth.

Sorry if this just adds to the confusion...

PS: this seems contradictory to me, I think of tooth "depth" and "height" as being the same thing

"tooth 5mm deep (mild steel) and 7mm tooth height"

Another consideration is the size of the sensor. The "pole" in the sensor, whether VR or Hall, has to be somewhat matched to the size of the target (wheel teeth). I would use a physical tooth size as suggested by the sensor vendor, even if it meant dropping back to 36-1. In my case I have a thin (1/8" thick) wheel with about .200" for teeth and .200" for gaps, about 1/8" deep. But, my VR sensor is only 3/8" OD, so the pole is about 1/8" diameter and well-matched to the size of the wheel teeth.

Sorry if this just adds to the confusion...

PS: this seems contradictory to me, I think of tooth "depth" and "height" as being the same thing

"tooth 5mm deep (mild steel) and 7mm tooth height"