Currently working on a MS3X powered Toyota 3SGTE (MS3X ready and waiting but engine build holding me up)

I was planning to use the stock Nippon Denso CAS, which uses a 24 tooth wheel and 1 tooth wheel in the dizzy to work out cam and crank angle from the cam. - It has been megasquirted successfully a few times, but does have some problems.

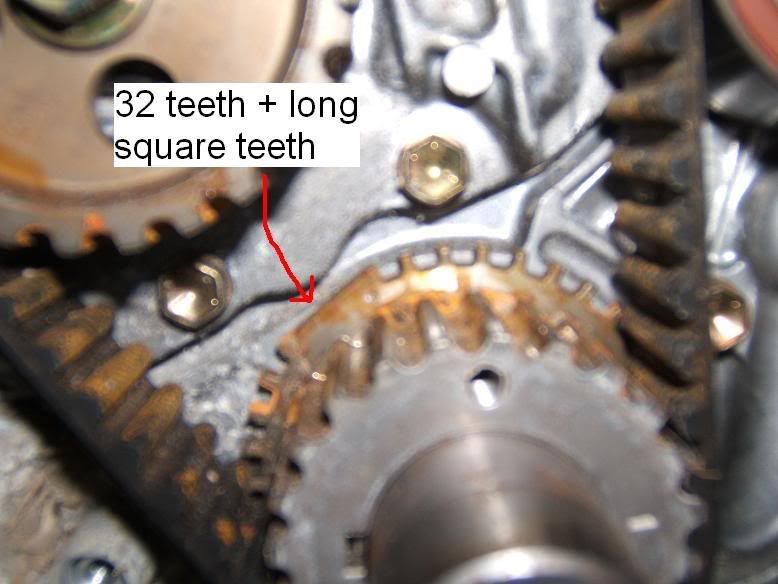

I've recently seen a neat OEM solution. - Using an oil pump from a 5SFE engine, which has a mount for a crank angle sensor (and is a high volume pump), combining this with a crank timing gear from a Gen 4 3SGTE (has 32+1 large tooth wheel integrated), will give me a ready made easy to install and reliable crank angle sensor.

I think I would then run just the 1 tooth VR sensor from the CAM and the crank sensor - I hope this would then eliminate all the cross interference etc. that the CAS suffers from.

Question is has anybody done this before?

And how would I set up my MS3X both in terms of hardware and config to run this?

Currently I have followed all of the instructions for 2x VR inputs assuming I would use the 2x VR sensors in the CAS unit. I expect the 5SFE crank sensor is also a VR sensor, will have to check.

Will the MS3 support the 32 + 1 long tooth crank wheel with a single tooth Cam wheel for sequential spark and injection??

Thanks

Dan