No need to be sorry and thanks for the feedback. I agree with you on through hole for through hole and likewise for SMD, which is what prompted me to ask the question on here.

The problem I'm running into is that there doesn't appear to be a source for through hole VND5N07 components (at least through digikey and mouser) in quantities of less than 3000 approximately. The SMD variants can be bought one at a time.

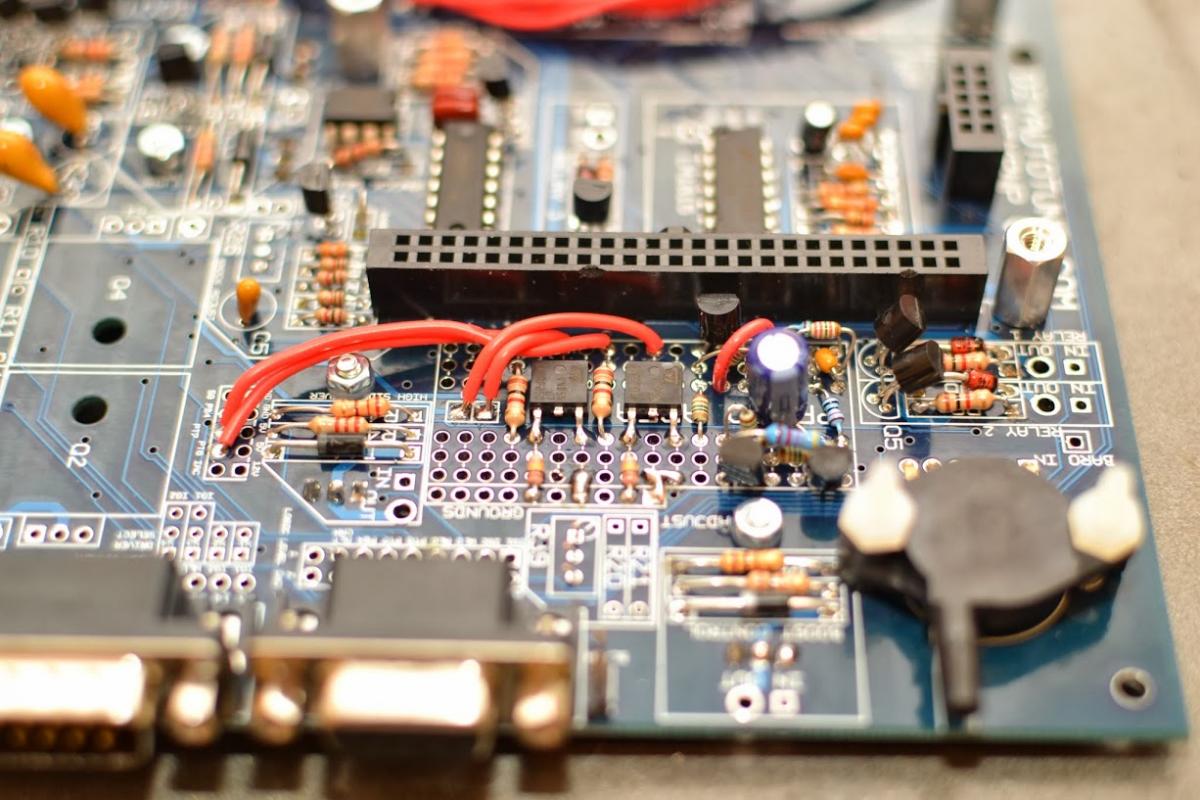

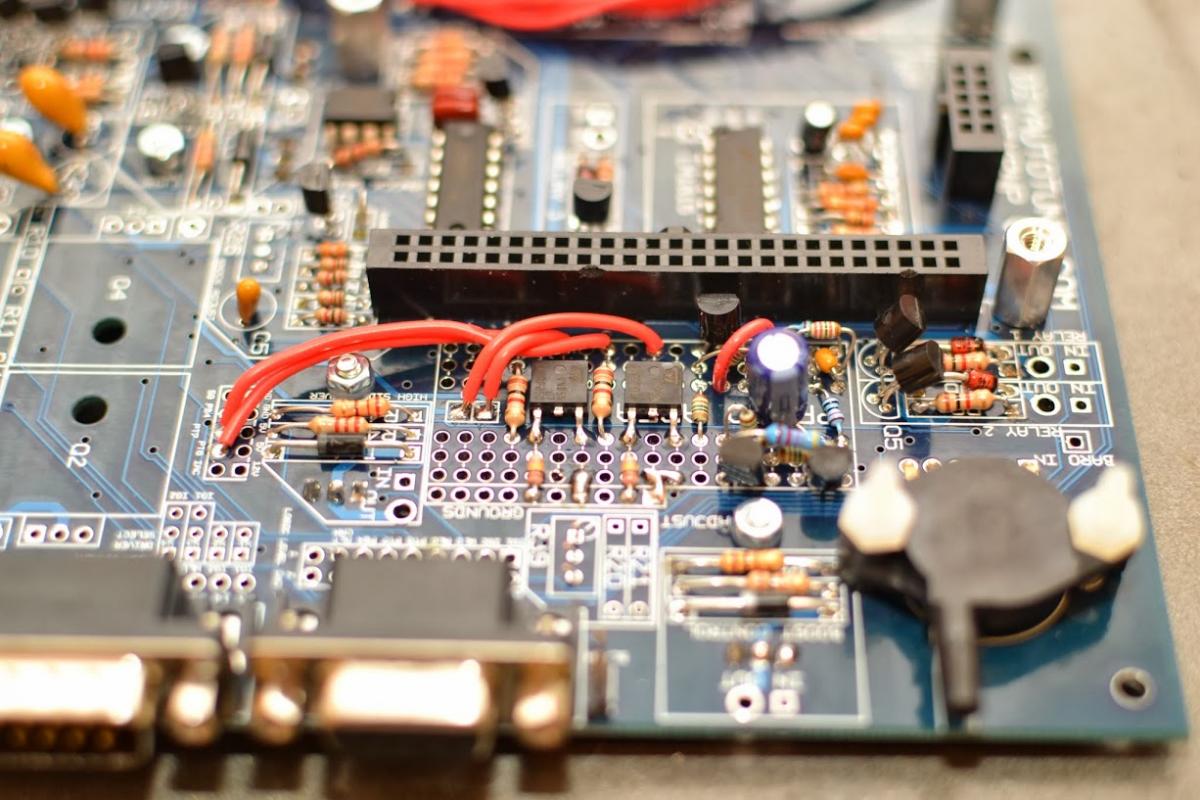

I'm trying to mimic the following board layout:

In the picture, it's clear that the INJ3/4 outputs are routed from the through holes in the proto area, but what can't be seen is how the drain is brought down to the through hole.

I agree concerning your assessment of best practice vs least likely to fail; are there any recommendations for attempting this in order to minimize the possibility of failure? I would love to use a through hole component, but am striking out. Additionally, the sequential mod for DIYPNPs is fair, but I was honestly hoping to take a more DIY approach for the purposes of learning.