Measuring crankshaft acceleration cylinder to cylinder

Moderators: jsmcortina, muythaibxr

-

TheSilverBuick

- Experienced MS/Extra'er

- Posts: 357

- Joined: Thu Feb 02, 2012 9:08 am

Measuring crankshaft acceleration cylinder to cylinder

Do any of the megasquirts have the capability to measure if the crankshaft sped up or slowed down after each ignition event? I guess it would be measuring the time between each ignition event and recording that time in a datalog fashion? Basically trying to measure the output of each cylinder against the output of the other cylinders. Of course with a cam sensor the actual cylinders could possibly be tracked, so that say because air/fuel distribution was uneven that a cylinder would show up as under/over performing? Say the firing order on a 4 cylinder was 1,2,3,4, and in the time of say 4 crankshaft revolutions (two ignition rounds) it could see that the time between cylinder 2 and cylinder 3 took a bit longer (or was quicker) than between 1&2, 3&4 or 4&1, so that timing or fuel could be adjusted for just cylinder 2 to bring it up to speed? I would think if this is possible and with a cam sensor to reference cylinder 1 that a statistical chart could be made pretty quickly showing which cylinders are contributing more HP and which are contributing less based on the pattern/trend of time between ignition events at a fixed throttle position and short time period of sample interval. For non-sequential setups could at least identify if the engine has a bit imbalance on the cylinder's output, rather it be fuel, timing, ring seal, etc. Can a standard 36-1 wheel have high enough resolution? Or would it require a lot more resolution?

Has it been done? Are these thoughts just ridiculous? I'm just wondering if could be a way to help tune an engine for better performance short of dyno'ing.

Has it been done? Are these thoughts just ridiculous? I'm just wondering if could be a way to help tune an engine for better performance short of dyno'ing.

"Hey, at least the Skylark proves that even a messy hack can patch together a reliable EFI system. I can't think of a time the MegaSquirt has left me stranded since installation ~100,000 miles ago."

Drag Week 2011, 2012 & 2015. - BB N/A - 1977 Skylark w/Buick 455 EFI and TKO-600!

Drag Week 2011, 2012 & 2015. - BB N/A - 1977 Skylark w/Buick 455 EFI and TKO-600!

-

TheSilverBuick

- Experienced MS/Extra'er

- Posts: 357

- Joined: Thu Feb 02, 2012 9:08 am

Re: Measuring crankshaft acceleration cylinder to cylinder

Thinking a bit more about this. If the delta (change) of time each cylinder took to get to the next ignition event compared to it's previous rotation could be displayed/logged then have all the cylinders averaged to compare which are high and low. Might need a couple revolutions to sort out or some fancy math like (delta)/(720* rotation time) to make it meaningful to the user...

Looking at the ignition calculations (http://www.megamanual.com/ms2/wheel.htm), it looks like the calculation tries to predict when the next tooth will pass, does it record when tbe tooth actually does pass or just restarts the calculating?

Looking at the ignition calculations (http://www.megamanual.com/ms2/wheel.htm), it looks like the calculation tries to predict when the next tooth will pass, does it record when tbe tooth actually does pass or just restarts the calculating?

"Hey, at least the Skylark proves that even a messy hack can patch together a reliable EFI system. I can't think of a time the MegaSquirt has left me stranded since installation ~100,000 miles ago."

Drag Week 2011, 2012 & 2015. - BB N/A - 1977 Skylark w/Buick 455 EFI and TKO-600!

Drag Week 2011, 2012 & 2015. - BB N/A - 1977 Skylark w/Buick 455 EFI and TKO-600!

-

Peter Florance

- Super MS/Extra'er

- Posts: 3653

- Joined: Fri Apr 02, 2004 8:40 pm

- Location: Virginia Beach, VA

- Contact:

Re: Measuring crankshaft acceleration cylinder to cylinder

Nothing to add but I'm going to follow this thread.

Peter Florance

PF Tuning

81 BMW Euro 528i ESP Car

60-2 Wheel LS2 Coils, Low Z Inj

Co-Driver 1999 BMW E46 DSP car.

PF Tuning

81 BMW Euro 528i ESP Car

60-2 Wheel LS2 Coils, Low Z Inj

Co-Driver 1999 BMW E46 DSP car.

-

jsmcortina

- Site Admin

- Posts: 39617

- Joined: Mon May 03, 2004 1:34 am

- Location: Birmingham, UK

- Contact:

Re: Measuring crankshaft acceleration cylinder to cylinder

I had plans to add this when Ken and I first started on the 1.1 code by measuring the length of each ignition period (from a predefined angle.) I haven't got around to it yet.

James

James

I can repair or upgrade Megasquirts in UK. http://www.jamesmurrayengineering.co.uk

My Success story: http://www.msextra.com/forums/viewtopic ... 04&t=34277

MSEXTRA documentation at: http://www.msextra.com/doc/index.html

New users, please read the "Forum Help Page".

My Success story: http://www.msextra.com/forums/viewtopic ... 04&t=34277

MSEXTRA documentation at: http://www.msextra.com/doc/index.html

New users, please read the "Forum Help Page".

-

TheSilverBuick

- Experienced MS/Extra'er

- Posts: 357

- Joined: Thu Feb 02, 2012 9:08 am

Re: Measuring crankshaft acceleration cylinder to cylinder

I will hope and watch for it in a future update then. Thanks

"Hey, at least the Skylark proves that even a messy hack can patch together a reliable EFI system. I can't think of a time the MegaSquirt has left me stranded since installation ~100,000 miles ago."

Drag Week 2011, 2012 & 2015. - BB N/A - 1977 Skylark w/Buick 455 EFI and TKO-600!

Drag Week 2011, 2012 & 2015. - BB N/A - 1977 Skylark w/Buick 455 EFI and TKO-600!

-

glenneaux

- MS/Extra Newbie

- Posts: 23

- Joined: Thu Oct 06, 2005 5:35 pm

- Location: Sale, Gippsland, Victoria, Australia

Re: Measuring crankshaft acceleration cylinder to cylinder

Did this ever get another look in James?

Sent from my Nexus 5 using Tapatalk

Sent from my Nexus 5 using Tapatalk

-

kaeman

- Master MS/Extra'er

- Posts: 643

- Joined: Sun Nov 06, 2005 12:31 am

- Location: NORTHERN CALIFORNIA

Re: Measuring crankshaft acceleration cylinder to cylinder

could you look at the log file from either the composite logger or the tooth logger, doesn't that give you a display in milliseconds between the events or how long each tooth was. then look at the pattern, of the 35 teeth on a 36 -1 wheel with a 4 cylinder engine you would have 2 ignition events per revolution, or 4 per revolution for a v8. I believe that one of the views show the length of time each tooth was. should be able to see differences there if you brought the file into excel or some other spread sheet.

64 el camino, 383 SBC, 11.7 to1 CR, accufab tb/rhs intake, 44lb injectors, trick flow heads, xr292r solid roller cam, belt drive camshaft, dry sump oil system, 2400 stall, turbo 350, spooled 9 inch, strange axles, 3.89 gears, dual wideband, full sequential fuel/cop, MS3x using 1.4.1 code.

-

billr

- Super MS/Extra'er

- Posts: 6828

- Joined: Sun May 15, 2011 11:41 am

- Location: Walnut Creek, Calif. USA

Re: Measuring crankshaft acceleration cylinder to cylinder

That is my thinking, too. You can certainly see variations in crank speed during cranking.

-

jsmcortina

- Site Admin

- Posts: 39617

- Joined: Mon May 03, 2004 1:34 am

- Location: Birmingham, UK

- Contact:

Re: Measuring crankshaft acceleration cylinder to cylinder

The trigger logger will show you this approximately (all firmwares.)

MS3 has a debug option to record per-cylinder data into the "Generic Sensor" channels.

James

MS3 has a debug option to record per-cylinder data into the "Generic Sensor" channels.

James

I can repair or upgrade Megasquirts in UK. http://www.jamesmurrayengineering.co.uk

My Success story: http://www.msextra.com/forums/viewtopic ... 04&t=34277

MSEXTRA documentation at: http://www.msextra.com/doc/index.html

New users, please read the "Forum Help Page".

My Success story: http://www.msextra.com/forums/viewtopic ... 04&t=34277

MSEXTRA documentation at: http://www.msextra.com/doc/index.html

New users, please read the "Forum Help Page".

-

TheSilverBuick

- Experienced MS/Extra'er

- Posts: 357

- Joined: Thu Feb 02, 2012 9:08 am

Re: Measuring crankshaft acceleration cylinder to cylinder

I need to go back and try this.

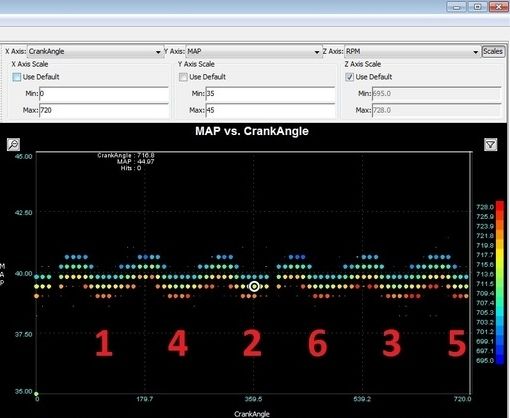

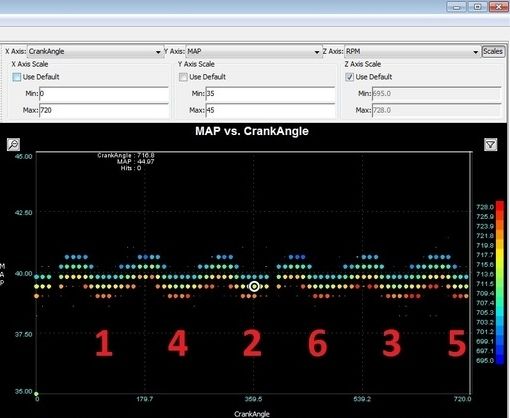

For both my Megasquirt'd cars I've made MAP plots against crank angle to look for "low pulling" cylinders, or more or less a balance test, but nothing has ever stood out enough for me to say something definitive is going on.

(I'm fairly certain I have the labels of the cylinder drawing the vacuum at each low off by two cylinders compared to crank angle, zero angle is TDC after compression of #1, induction of #1 is likely labeled #3)

For both my Megasquirt'd cars I've made MAP plots against crank angle to look for "low pulling" cylinders, or more or less a balance test, but nothing has ever stood out enough for me to say something definitive is going on.

(I'm fairly certain I have the labels of the cylinder drawing the vacuum at each low off by two cylinders compared to crank angle, zero angle is TDC after compression of #1, induction of #1 is likely labeled #3)

"Hey, at least the Skylark proves that even a messy hack can patch together a reliable EFI system. I can't think of a time the MegaSquirt has left me stranded since installation ~100,000 miles ago."

Drag Week 2011, 2012 & 2015. - BB N/A - 1977 Skylark w/Buick 455 EFI and TKO-600!

Drag Week 2011, 2012 & 2015. - BB N/A - 1977 Skylark w/Buick 455 EFI and TKO-600!