He's been hanging with VW guys again, the V9 is half of the W12 and the big brother of the VR5.MegaScott wrote:Brian, V9? what were you smoking?

That's no kidding, they are really cooll.Great work, those Spark pics Rock!

Eric

Moderators: jsmcortina, muythaibxr

racingmini_mtl wrote:Paul,

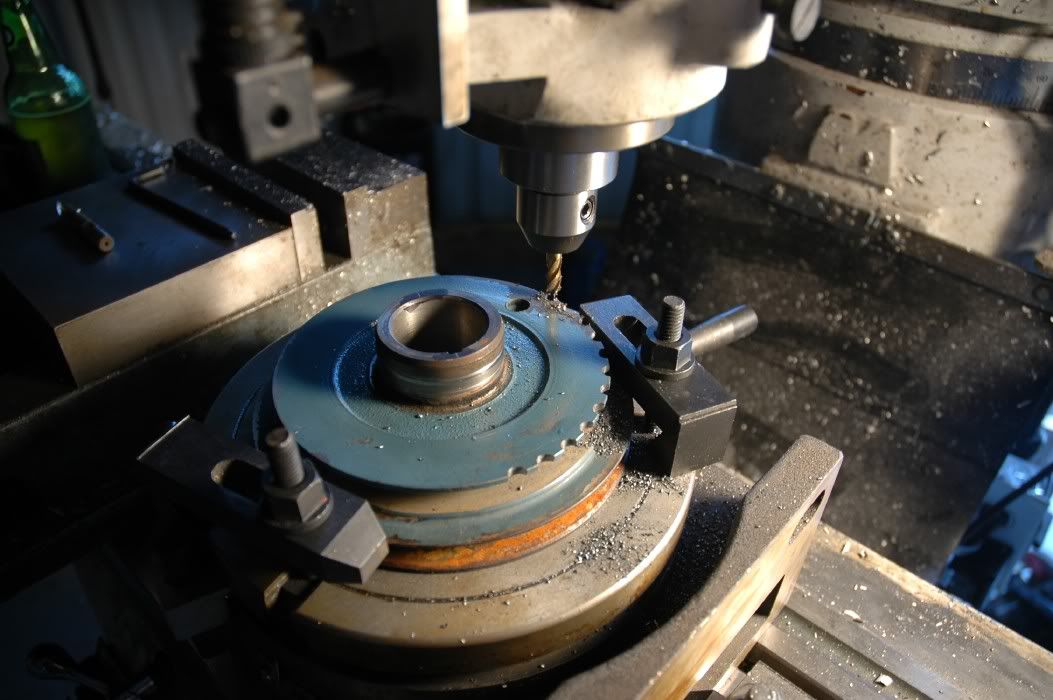

Have you tried to reverse the cutter blade so that the ramp side and the steep side (I'm not sure how else to describe them) of the tooth are not seen in the same order? ......I assume that the highly unsymmetrical teeth cause the zero crossing to behave differently that with the normal symmetrical teeth. That could influence how the EDIS module reacts.

Anyway, just a thought.

Jean

My concern is the type of material the blades and teeth are made from.lemans70sport wrote:Karch,

Just buy 2 blades and tack weld them together. I would want to modify the teeth so they are closer to square but that is a very cool and cheap alternative to having a custom wheel made.

Karch wrote:If I were to get a few 8" diameter wheels made up, could you test one out for us for an EDIS-8?

.............

Thanks again, and please let me know if you will consider testing for us.

Karch