I hope this is the most appropriate section to place this. I also want to say straight away that I may be changing where I host all my images and files shortly and so if any images or files are missing, please send me a PM.

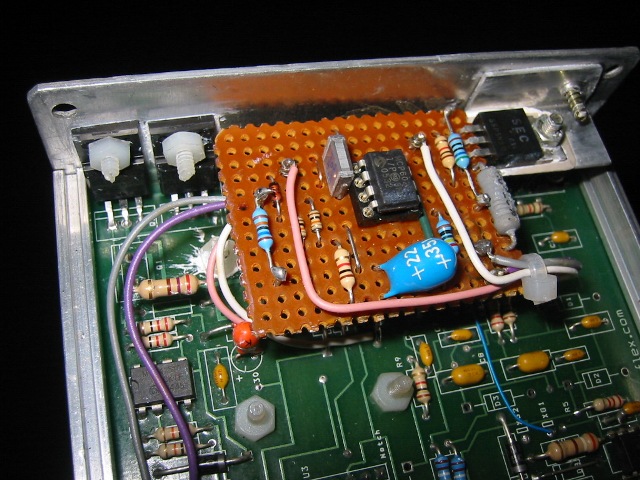

First of all here's an image of what I have produced, and an explanation shall follow.

Background

My project is a 16V G60 engine which is currently in a Golf MK2, and will eventually be installed into my Golf G60 Syncro. I am running MS1 with MSNS-E 029v.

The standard VW 8V G60 engine runs a Bosch two-wire ISV, and I really wanted to be able to continue using such an ISV on my 16V G60. The Bosch ISV that I am using is the type that is supposed to be slightly open at 0% (to enable 'limp home' mode, I suspect); and closed at 25%. I can look up its part number if anyone requires it.

I initially had the ISV being controlled directly by the voltage PWM from the MS1 using a suitable power FET. Now I found that to have reasonably good resolution (steps) of duty cycle to the ISV, I had to drive the ISV at a frequency below 100Hz. To get usable resolution from the ISV I had to use a duty cycle of somewhere between 50 and 70Hz (I can't quite remember which). Although this did kind of work and did allow reasonable idle control, running at such a low frequency isn't the correct mode of operation for these ISVs. At this low frequency the piston in the ISV is just banging back and forth. I wouldn't have cared so long as it worked, but the ISV made an awfully loud noise that I couldn't stand.

The ISV should actually be operating at around 150Hz (the Digifant ECUs operate it at 147Hz). Because of the higher frequency, the piston isn't banging back and forth anymore. Instead it is 'suspended' at a point which obviously depends on duty cycle, and the ISV just makes a quiet buzzing noise - much more pleasant! The problem now though is that at this frequency, slight increases in DC appeared to open the valve up far too much, far too quickly. It was like this: At, for example, a DC of 20, the ISV might have given me 1000rpm. At 21, it might have been 1300rpm. You get the picture.

I made some measurements on a G60 that was running the standard Digifant ECU. I found that at idle, the ISV was getting what looked like 40% duty cycle (and when the engine was revved, the DC went down to 28% to close the valve and prevent boost going backwards through it). But if I attempted to give the ISV anything near this amount of duty on my engine, I'd totally rev the nuts off my engine. So this question was bugging the hell out of me: Why is it that the Digifant I controller can operate the ISV at around 40% duty at idle, and yet if I apply anything near that duty from the MegaSquirt controller, the engine revs far too highly?

So what I decided to do was reverse engineer the ISV control circuitry in both the Digifant II (8V GTI MK2) and Digifant I (G60) controllers. And I found the answer. The Digifant controller is not simply PWMing the ISV solenoid coil fully on and fully of. In actual fact, the controller is providing a controlled current ramp to the ISV.

When you scope the voltage across the ISV, you have a reasonably square waveform that looks like the ISV is just being switched on and off (G60 ECU PWM rate is 147Hz). But it isn't. For each PWM cycle during the 'on' period, the current in the ISV starts at some low value, and linearly ramps up. Then obviously during the dead time the current snaps to zero.

Why have Bosch controlled the ISV like this? Well, I have built a copy of the Bosch G60 ECU ISV circuit to fit into my MegaSquirt. When testing it on the bench, I've realised the following things:

1. The method of controlling the current through the ISV means that the ISV opening amount won't be affected by fluctuating battery voltage. Now initially I thought this wouldn't be important because surely the ISV closed loop control is going to compensate for supply voltage changes. But the problem comes when you apply throttle, which is the time when you want the ISV to be fully closed. At this time the ISV is no longer being closed-loop controlled; it has a fixed duty cycle applied (28%) in order to fully close it. If changing battery voltage (i.e. increased voltage from the alternator when you floor it) is able to affect the ISV opening then I suppose you could start losing boost through the ISV.

2. I've built an ISV tester board that allows me to vary the PWM to the ISV using up / down buttons. Now when I originally used this board to control the ISV by simply using on / off action using nothing more than a MOSFET, the ISV opening amount varied linearly with PWM duty. But, using the Bosch circuit, it's now more logarithmic. What I am finding is that the ISV is quite slow to open for up to 50 or 60% duty, but above that, it starts to open more and more. So why is this good? Well, I think that it means that for most of the duty cycle range, a wide duty range gives only a small ISV opening, with finer steps. This gives more precise ISV control and will give the MegaSquirt greater resolution to play with. But why is this better than simply shoving a resistor in series with the ISV? Well, the ISV is able to start opening by larger amounts if you swing the duty up to 80%. A large ISV opening is required during cranking. So: the ISV can be opened wide for cranking, but at the same time we have a great resolution of control around the point where the ISV just starts to open, allowing higher resolution of idle control. This is important on the MegaSquirt where the PWM resolution starts to become pretty poor when you start using frequencies like 150Hz.

Circuit Description

The circuit is simple to build. It consists of a MOSFET or NPN transistor that you'd typically chuck into the MegaSquirt in order to have ISV control. But we're no longer simply banging the device on and off. What the circuit introduces is a small value wirewound resistor in series with the transistor. This small value resistor (less than an ohm) and the FET/transistor now sit within the feedback loop of an operational amplifier. This means that whatever voltage is input into this op-amp determines the current flow through the ISV. The second bit is an op-amp integrator. This integrator provides a voltage ramp which controlled by the digital on/off PWM from the CPU.

So the circuit is quite simply a dual op-amp, a couple of capacitors, a few resistors, a little wirewound resistor that I stole from a scrap Digifant II ECU, and whatever MOSFET I could find amongst all my crap. The circuit fits onto a little 1.5" square bit of Veroboard.

PDF Schematic

http://www.introspectiv.eclipse.co.uk/1 ... V_r0_1.pdf

Conclusion

I know that many people have had success of driving a Bosch two-wire ISV straight from MS. I can only assume it's because those people are using MS2, which presumably offers much higher level of resolution and thus can voltage-PWM the ISV directly at 150Hz and still give small enough DC steps.

I am now getting good results from my ISV, although I still need to investigate a way of preventing the engine near-stalling when I operate the powered steering while the car is static.

I'll come back and edit this post shortly to refine it a little more. I'm quite tired now, so apologies if any of it doesn't make sense!

Cheers,

Trev