I'm currently in the process of building a Discovery Ute, and below is where I am currently at:

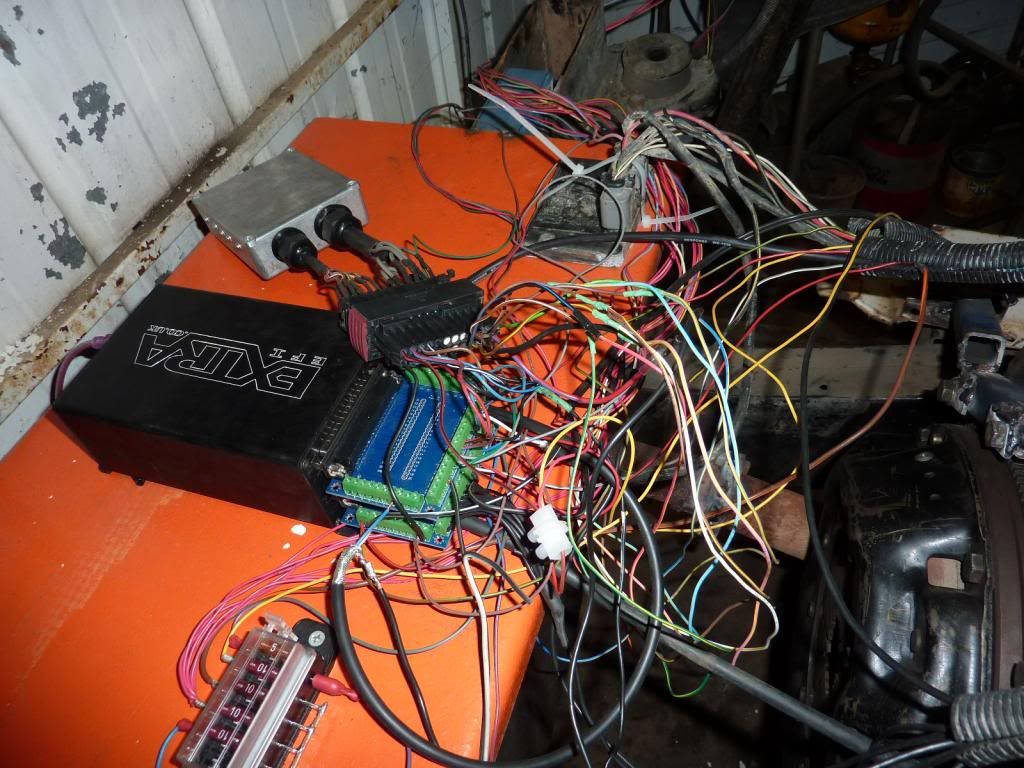

Anyway, the car will be powered by a Twin Turbo Land Rover 3.9L engine with 8:1CR on LPG only. As the subject suggests, I intend to use MS3 to control the ignition in wasted spark mode and the fuel sequentially.

I'm in the process of desiging the wiring and circuitry to make it all happen, I've found heaps of information for the configuration of the crank signal, cam signal, coolant, air temp etc. But I haven't found any information at all on running the vapour LPG injection system (the injectors and the needed sensors). What I do know is this:

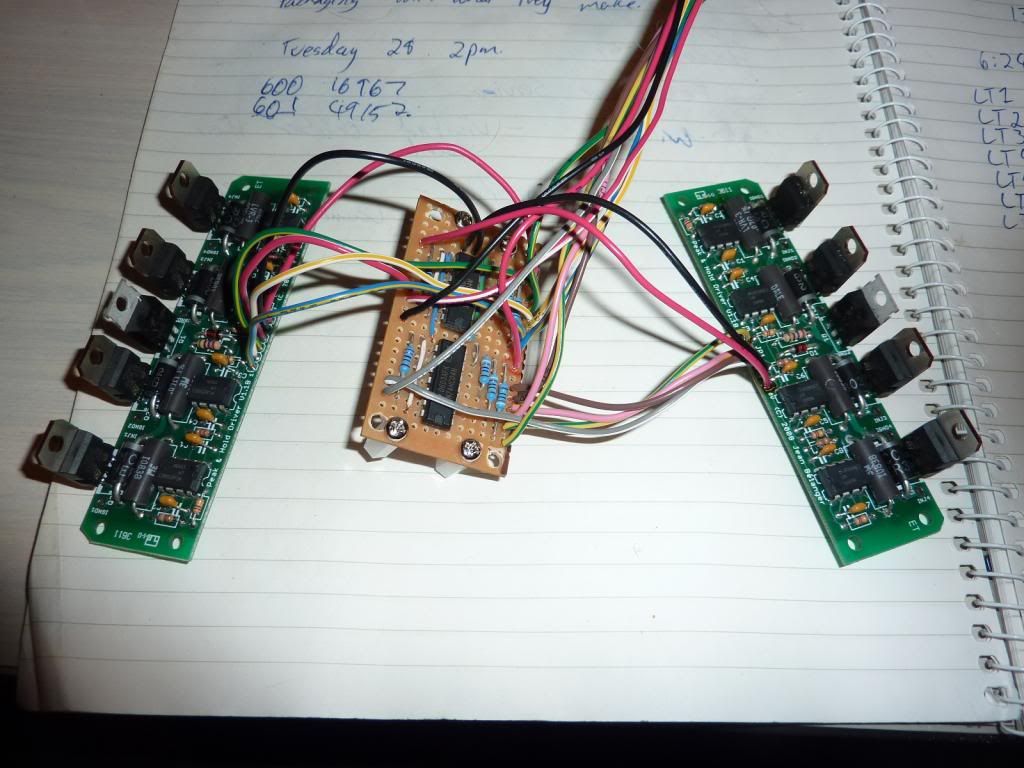

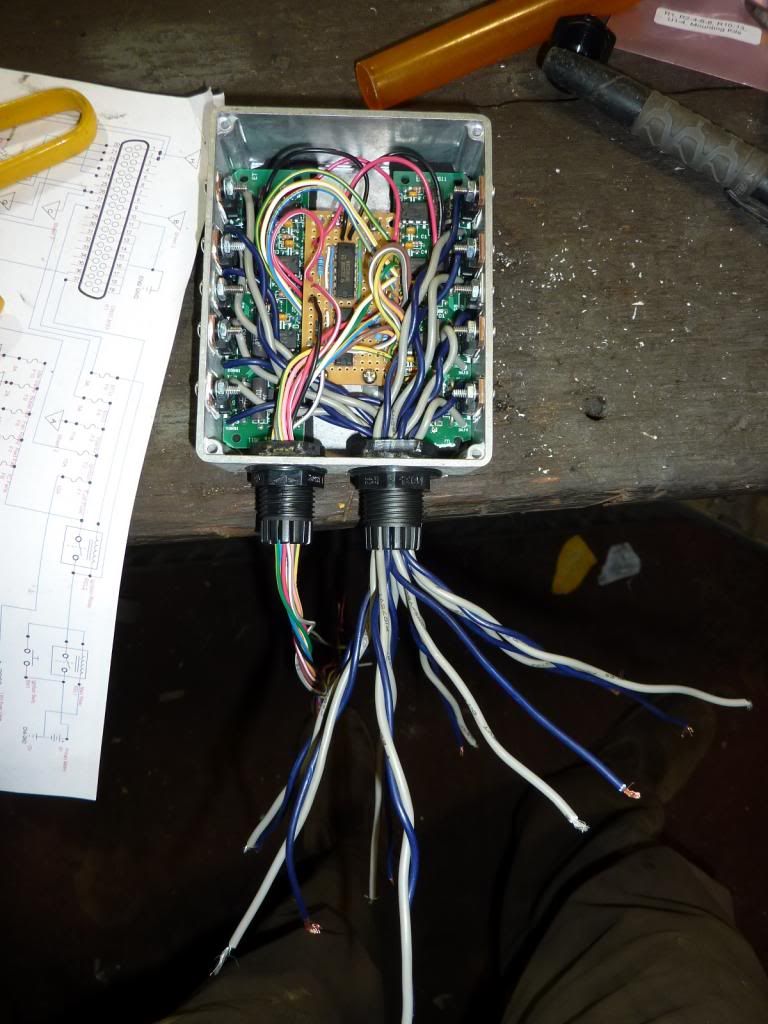

*LPG injectors are low impedance and need the Peak & Hold Circuit Board

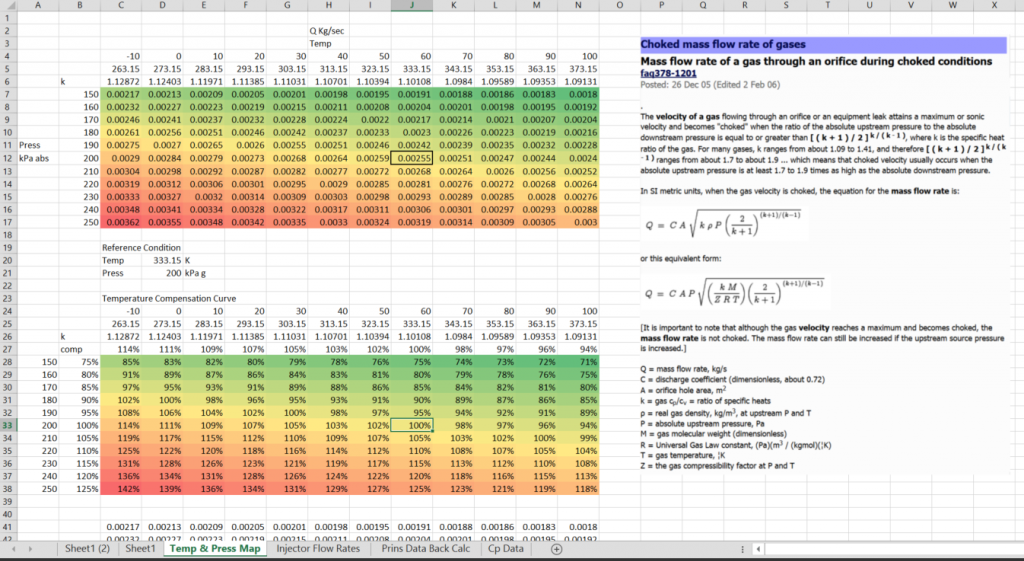

*To correctly meter the fuel the pressure and temperature in the LPG fuel rail needs to be known

*MS3 natively supports LPG injection

What I am struggling with is:

*What sensors or kits have people used to get MS3 to run vapour LPG injection?

*How are the sensors wired to MS3?

*How is MS3 configured to use the sensor data in adjusting the fuel metering?

Can anyone provide me with some information here? I have never used a MS ecu before so i'm trying to get my head around it all.

Thanks,

Stirling